Optimizing the Quote-to-Cash Process with CPQ

Learn how CPQ software streamlines the quote-to-cash process by improving configuration, pricing, quoting, and cross-system integration.

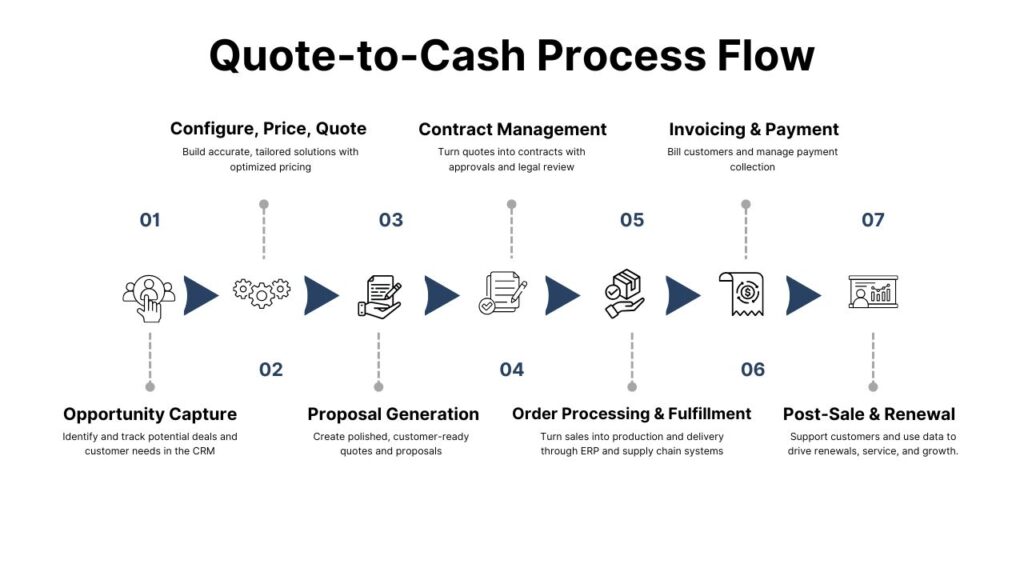

The quote-to-cash (QTC) process spans every stage of the sales cycle, from opportunity creation to final billing and post-sale analysis. How well this machine is oiled dictates how effectively your company generates revenue and delivers customer excellence.

While misalignment between functions, disconnected systems, and manual handoffs often stymie this process, the solution isn’t necessarily a single end-to-end platform. Strategic integration of specialized systems, each optimized for its part of the journey, creates a smooth, automated workflow that keeps sales, product, legal, and finance teams working in perfect sync. And at the very beginning of this optimization is Configure, Price, Quote (CPQ).

Understanding the Quote-to-Cash Process

The QTC process is comprehensive, involving many steps and many systems across your tech stack. It can be broken down into seven core steps:

1. Opportunity capture: Sales teams identify potential deals in a CRM, recording initial customer requirements and contextual information.

2. Configuration, pricing, quoting: For manufacturers, this crucial step involves configuring viable product solutions and determining accurate pricing based on complex specifications, customizations, and volume.

3. Proposal generation: Creating professional, accurate customer-facing documents that communicate offerings, pricing, and terms.

4. Contract management: Converting approved quotes into legally binding agreements through CLM systems, often requiring multiple reviews and approvals.

5. Order processing & fulfillment: Translating sold configurations into actionable manufacturing and delivery instructions in ERP systems.

6. Invoicing & payment: Billing customers accurately according to contract terms and tracking payment completion.

7. Post-sales & renewals: Managing ongoing customer relationships, maintenance contracts, and identifying expansion opportunities.

Where the Quote-to-Cash Process Often Misses the Mark

Where the Quote-to-Cash Process Often Misses the Mark

Across CRM, ERP, CPQ, CLM, and other systems—along with manual processes—inefficiencies often occur at critical points in the QTC process, leading to a number of potential bottlenecks:

- Manual data entry and disconnected systems delay quoting and approvals and slow down sales cycles.

- Revenue leakage occurs due to inconsistent pricing and discounting.

- Complex product configurations increase the risk of quoting mistakes when managed manually.

- Pricing, contract, and discount approvals stall deal progression.

- A lack of integrated data leads to a lack of transparency for decision-making.

For companies selling highly configurable or engineer-to-order products, the configuration step presents unique challenges due to product complexity. Rather than seeking a one-size-fits-all QTC solution, these organizations benefit most from implementing a specialized CPQ solution designed for complex configurations that can integrate effectively with their existing CRM, ERP, and CLM systems.

5 Ways CPQ Optimizes the Quote-to-Cash Process

CPQ excels at addressing the core configuration, pricing, and quoting challenges that impact the broader QTC journey. By focusing on getting this critical middle portion right and ensuring smooth integration with surrounding systems, companies selling complex products can achieve both specialized functionality and seamless process flow.

1. Streamlining the Configuration Process

At the heart of CPQ’s value is its ability to handle complex product configurations with ease. For companies selling highly configurable products, CPQ eliminates the error-prone spreadsheets and manual processes that slow down sales. By embedding engineering rules and constraints directly into the configuration engine, CPQ ensures every configuration is valid by embedding engineering rules and constraints directly into the configuration engine, thus optimizing for the customer’s needs without requiring constant engineering involvement. It also helps reduce errors that affect downstream processes like contract accuracy, order fulfillment, and invoicing.

When integrated with your CRM, this configuration data flows seamlessly from opportunity to quote, with customer information pre-populated and product specifications accurately captured.

2. Ensuring Pricing Accuracy and Consistency

Complex products demand sophisticated pricing models. CPQ brings discipline to pricing by centralizing all pricing rules, discount structures, and approval workflows in one system. This eliminates the revenue leakage that occurs when sales teams rely on outdated price lists or inconsistent discounting practices.

With proper integration, pricing insights from your ERP can flow into CPQ, ensuring that quotes reflect current costs, inventory availability, and production capacity—all factors that impact profitability in complex selling environments.

3. Accelerating Quote Generation and Approval

The ability to quickly generate professional, accurate quotes directly impacts sales velocity. CPQ automates the creation of customer-facing documents, incorporating not just pricing but product visualizations, technical specifications, and commercial terms.

By connecting your CPQ system with approval workflows in surrounding systems, even quotes requiring multiple levels of review can move quickly through the process, with all stakeholders having visibility into the exact configuration and pricing details they need to make decisions.

4. Creating a Single Source of Truth

CPQ becomes the authoritative record of what was sold, at what price, and with what specifications. When integrated with contract, order, and billing systems, this data flows through the entire QTC process so that what is quoted is exactly what gets contracted, manufactured, and invoiced. By doing so, you eliminate friction and reduce disputes caused by misalignment across the value chain.

5. Enabling Data-Driven Insights

Every quote created in CPQ captures valuable data, such as product choices, configurations, pricing strategies, and customer preferences. When analyzed, this data reveals patterns that improve pricing accuracy, highlight popular configurations, and inform future product decisions. These insights flow back into the sales, pricing, and post-sales processes, closing the loop and continuously optimizing the quote-to-cash journey.

Why One-Size-Fits-All QTC Solutions Fall Short for Complex Products

Companies that sell highly configurable or engineer-to-order products face unique challenges that generic QTC solutions often fail to address adequately. A single, all-encompassing QTC platform might promise simplicity through unification, but this approach frequently sacrifices depth for breadth.

The complexity of your products directly impacts your sales cycle in several ways:

- Technical validation requirements: Each configuration may need to be validated against engineering rules to ensure manufacturability.

- Custom pricing models: Pricing often depends on complex calculations based on materials, labor, and manufacturing processes.

- Visual configuration needs: Customers may need to see and interact with visual representations of complex products.

- Approval complexity: Non-standard configurations typically require multiple levels of specialized review.

- Integration with production systems: Detailed specifications must flow accurately to manufacturing systems.

These complexities demand purpose-built systems that understand the nuances of configurable products. Rather than forcing these specialized needs into a generic QTC platform, the more effective approach is to:

- Implement a purpose-built CPQ system designed specifically for complex product configuration.

- Focus on integration capabilities that allow specialized systems to communicate seamlessly.

- Maintain best-of-breed solutions across the QTC process while eliminating manual handoffs.

This approach allows you to get the specialized functionality needed for your complex products while still achieving the process efficiency that comes from integrated systems.

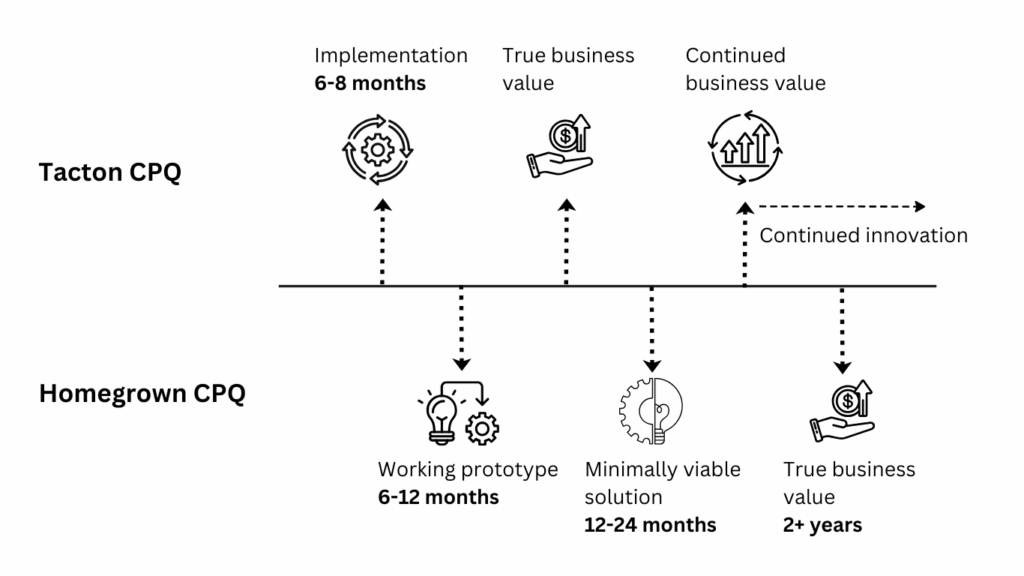

Accelerate Your Quote-to-Cash Process with Tacton

Selling highly configurable or engineer-to-order products comes with challenges, like long sales cycles, complex pricing, and slow approvals. Tacton CPQ helps you accelerate your QTC process at multiple touchpoints across the sales cycle, integrating easily with over 600+ different systems across CRM, ERP, CLM, and much more.

With Tacton, sales teams configure and price complex solutions instantly, avoiding errors and delays. By connecting your most important functions across the sales lifecycle through strategic integration, you can reduce your sales cycle while increasing value to your customers.

Ready to streamline your quote-to-cash process?