Smart Manufacturing: Key Innovations & Next Steps for Growth

Explore smart manufacturing concepts, technologies, and how its principles can extend beyond production to drive smarter selling.

Smart manufacturing is a booming field expected to grow from $233 billion to $479 billion over the next five years. Growing customer demands and production complexity are requiring brands to turn to emerging technology and automation tools to improve their operations and deliver a better experience for their teams and their customers.

It’s important to understand the core principles and technologies driving smarter production, from AI-driven automation to robotics. However, leading manufacturers aren’t stopping at production efficiency; they’re extending these principles beyond the factory floor to reimagine the buyer journey and commercial strategy for long-term growth. This evolution is shaping the future of manufacturing, turning operational excellence into a competitive advantage across the entire business.

What Is Smart Manufacturing?

Smart manufacturing uses advanced technology, such as robotics, AI, and cloud computing, to increase efficiency at every step of production. Unlike traditional manufacturing, which relies on stable, repetitive assembly lines, smart manufacturing is dynamic, leveraging real-time intelligence to optimize operations.

This category of manufacturing is quickly being adopted in facilities—often referred to as smart factories—across countries like China, the United States, and India.

Smart manufacturing typically involves three core components:

- Automation: Using technology to automate repetitive processes and complete tasks more quickly

- Quality Control: Using advanced technology to identify and correct errors, which helps prevent faulty products from going to market

- Optimization: Helping organizations analyze manufacturing data to optimize their processes and identify opportunities for reducing costs and waste

The primary focus of smart manufacturing is on enhancing production process efficiency. However, manufacturers should not stop at the production line, as these smart manufacturing principles—automation, data-driven optimization, and quality control—can also be extended to the customer’s journey and the sales process. By doing so, manufacturers can build a more agile and seamless operation across the entire business ecosystem.

The Benefits of Smart Manufacturing Processes

By reducing inefficiencies in production, smart manufacturing is not only lowering production costs but also enabling manufacturers to be more agile in responding to market shifts and evolving customer demands. The ability to adapt quickly strengthens manufacturers’ competitive edge and their ability to deliver high-quality products faster and more cost-effectively.

Manufacturers are seeing benefits like:

- Improved efficiency and productivity: Smart manufacturing systems help production teams increase their output without compromising quality. Robots, for example, can often complete rote manufacturing tasks faster than humans.

- Enhanced product quality: AI-powered IoT devices can identify and prevent possible manufacturing errors, resulting in higher-quality products.

- Real-time monitoring and maintenance: IoT sensors and devices constantly monitor your manufacturing systems, helping you schedule preventive maintenance and keep essential devices functioning properly.

- Cost reduction and resource optimization: AI and smart technology can help identify opportunities to save money throughout production. For example, they can create more efficient labor schedules or reallocate machinery for more efficient operations.

- Environmental sustainability: Smart manufacturing systems allow you to track the waste generated by your production processes and find ways to reduce it.

- Improved warehouse safety: Tools like IoT devices and digital twins identify possible safety risks, allowing you to address them and protect your team.

Manufacturers have the opportunity to build on these benefits by extending smart manufacturing principles to customer engagement. While smarter production improves profitability by reducing costs and inefficiencies, smarter selling enhances margins by driving deeper market penetration, strengthening customer relationships, and accelerating revenue growth.

The Smart Manufacturing Technology Powering Innovation

The benefits of smart manufacturing are clear, but how do smart factories get there? Several innovative technologies are used throughout smart factories to make operations more efficient.

Automation and Robotics

Many smart factories use robots to automate production processes, such as transporting items from place to place or assembling products. Automating these repetitive tasks gives employees more time to focus on complex challenges that require human input. It also helps factories increase their output and get products to market faster.

Internet of Things (IoT)

The Internet of Things is a network of devices connected to the internet that share data with other devices or systems. Smart thermostats, sensors, and security systems are common examples of IoT devices.

IoT devices monitor equipment performance, predict maintenance needs, and improve workplace safety. By minimizing downtime and ensuring consistent production, manufacturers can reliably fulfill orders and maintain high service levels for their customers.

Artificial Intelligence (AI)

AI is transforming smart manufacturing by enabling real-time decision-making, predictive analytics, and process optimization. For example, AI is often used in demand forecasting to analyze market trends, customer orders, and supply chain data, helping manufacturers better align production capacity with actual demand.

When integrated with IoT devices and other smart technologies, AI can analyze vast amounts of manufacturing data, identifying inefficiencies and quality issues before they become costly problems. Machine learning algorithms detect patterns in production performance, allowing manufacturers to predict maintenance needs, reduce downtime, and optimize resource allocation.

Cloud and Edge Computing

Instead of having physical servers on-premise, smart manufacturers are switching to cloud computing. Cloud-based systems enhance scalability and data access, while edge computing improves real-time processing for faster responses. These technologies ensure that real-time production insights are accessible across the organization, improving coordination between operations, engineering, and sales teams.

Digital Twins

A digital twin is a virtual replica of a real-life production system. It’s powered by data from the physical system, which is collected in real time. Digital twins are generally created using AI to optimize manufacturing processes. Digitizing these systems makes it easier to catch inefficiencies and optimize processes. You can also use digital twins to simulate future scenarios and see how your system would perform.

Blockchain

Blockchain ensures secure, real-time tracking of materials and compliance across supply chains. This transparency enhances trust with customers by providing verifiable sourcing and sustainability credentials for manufactured products.

Connecting Innovation with Business Strategy

As these technologies continue to evolve, they are not just reshaping production processes but also redefining how manufacturers interact with customers and bring products to market. The future of smart manufacturing will be driven by the seamless integration of these innovations with business strategy, so that companies can remain competitive in complex and dynamic markets.

The Next Evolution of Smart Manufacturing: Bridging the Gap to Smarter Selling

Smart manufacturing optimizes production to meet customer demands, but if buyer engagement remains outdated, much of that value is left untapped. Smarter manufacturing strategies should encompass how complex products are sold, not just how they’re produced or designed. As manufacturing technology advances, companies must integrate innovation with customer engagement and sales strategies. The future of manufacturing involves aligning production capabilities with customer needs.

How can the same principles (e.g., technological innovation, automation, quality control, data-driven decision-making) apply to smarter selling?

Sales Automation and Guided Selling

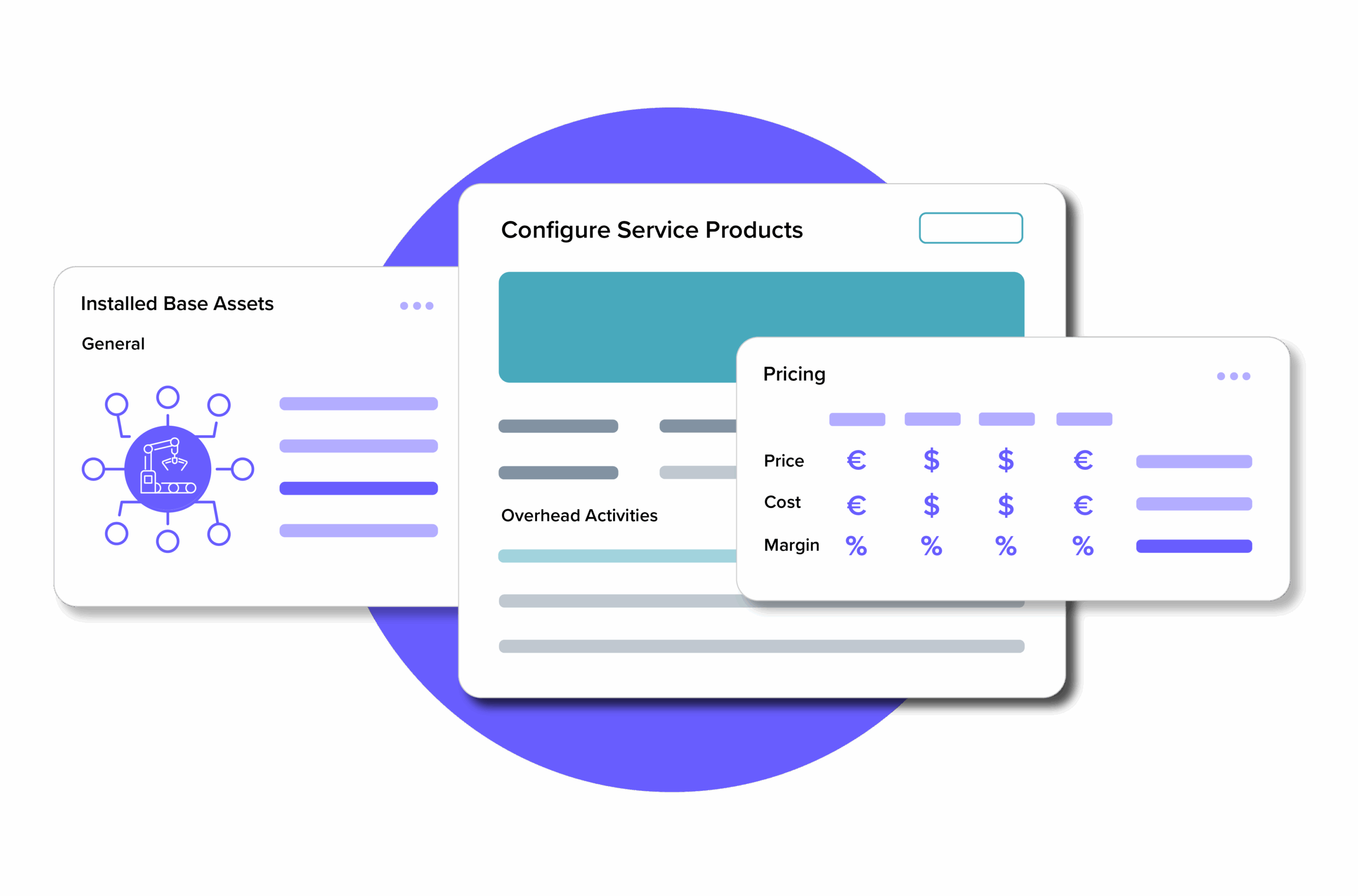

Manufacturers can automate sales processes by streamlining configuration and pricing of complex products. Configure, Price, Quote (CPQ) software, when used as a frontline sales tool, integrates product engineering rules with sales logic to help sales build solutions quickly and autonomously.

Emerging AI-driven guided selling tools can analyze customer needs, recommend optimal configurations, and ensure that what is sold aligns with production capabilities. This reduces errors and shortens sales cycles, while enhancing the buying experience with real-time, data-driven recommendations.

Pricing and Proposal Consistency

Just as quality control ensures high production standards, manufacturers can use sales automation to apply consistent pricing logic to quotes and proposals. By leveraging real-time cost and production data, manufacturers can offer dynamic pricing that reflects production constraints, competitive positioning, and profitability goals.

Visualization in the Buying Experience

Augmented Reality (AR) and Virtual Reality (VR) are changing how manufacturers showcase complex products, making the buying experience more interactive and informed. AR enables customers to visualize products in their real-world environment, while VR immerses them in a fully digital experience where they can explore configurations and customizations firsthand. By reducing reliance on physical prototypes and simplifying complex decision-making, these technologies help manufacturers communicate value more effectively and accelerate the path to purchase.

Data-Driven Sales Performance and Profitability Insights

Smart manufacturing principles don’t just improve operations; they also enable data-driven sales strategies. By leveraging analytics tools, manufacturers can track their most profitable products, assess sales performance across regions and industries, and identify opportunities for growth. AI-driven predictive analytics can further aid teams in forecasting demand and predicting customer behavior to adapt their sales strategies.

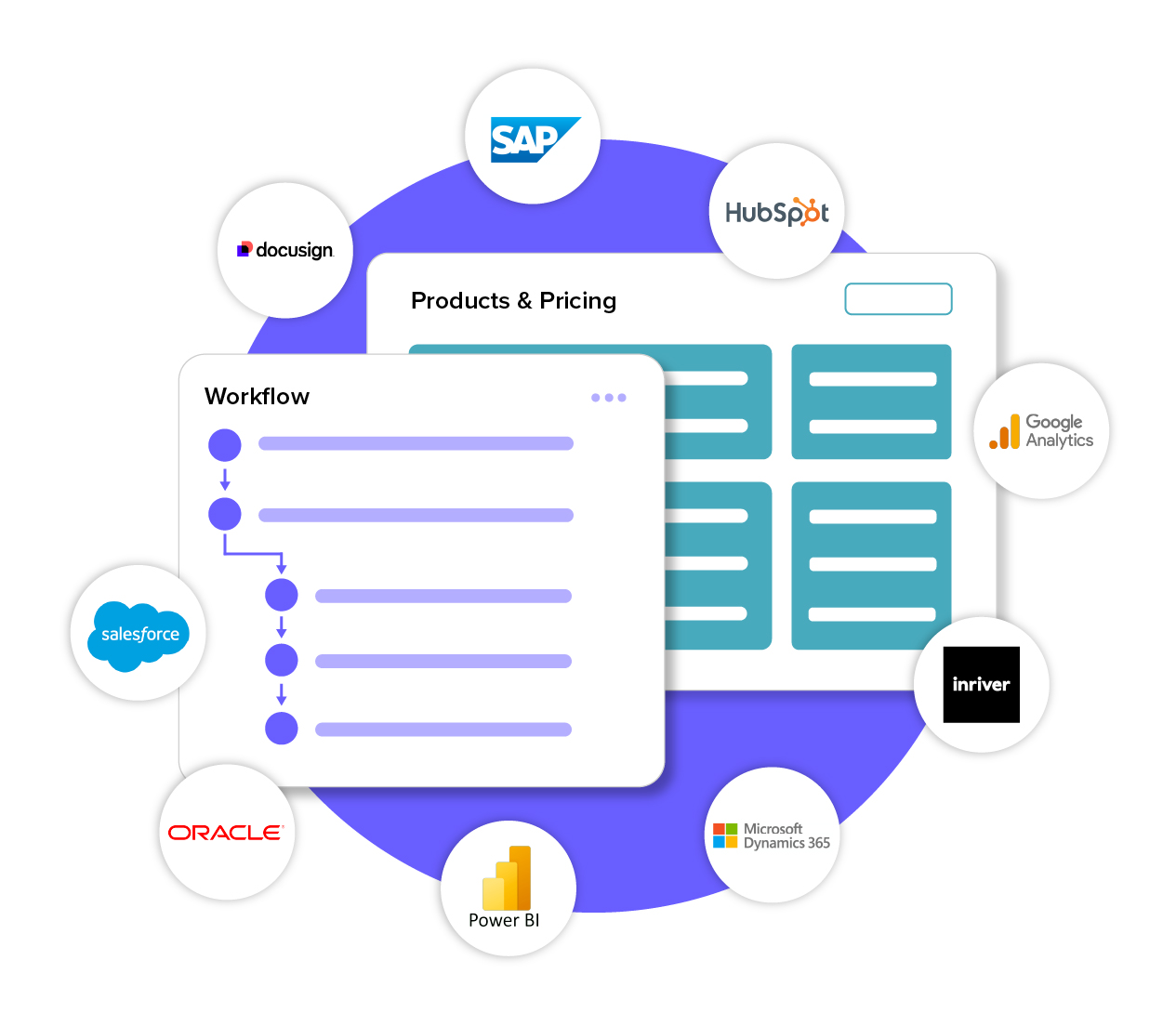

Efficiency Across Systems

Smart selling is most effective when data is seamlessly integrated across systems and teams can work with one source of truth. This connectivity ensures that sales teams have real-time access to production constraints, lead times, and engineering feasibility, resulting in a more accurate and efficient sales process that aligns with manufacturing realities.

Sustainability as a Sales Differentiator

Real-time tracking of carbon footprints, material choices, and sustainability metrics is no longer just for regulatory compliance, it’s a value driver in the sales conversation. Customers are increasingly prioritizing sustainable options, and manufacturers that integrate sustainability data into the sales process can better align with customer values and differentiate their offerings.

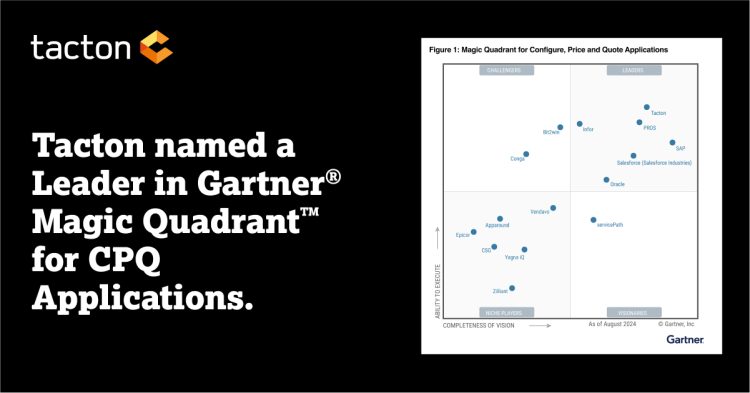

Embrace Efficiency with Tacton

Bridge the gap between production and sales by equipping your teams with the same efficiency and intelligence that drive modern manufacturing. Tacton’s CPQ solutions help you streamline complex configurations, apply real-time engineering and pricing rules for accurate quotes, and provide data-driven insights to optimize sales. As a 3x Leader in the Gartner® Magic Quadrant™ for CPQ Applications, we help manufacturers ensure every quote is manufacturable, profitable, and aligned with business goals—so you can sell with confidence and stay ahead in a competitive market.