Siemens Energy simplifies its product architecture and drives standardization

Discover how the energy technology giant deployed a common, modular architecture to free engineers from configuration validation and empower innovation.

The challenge

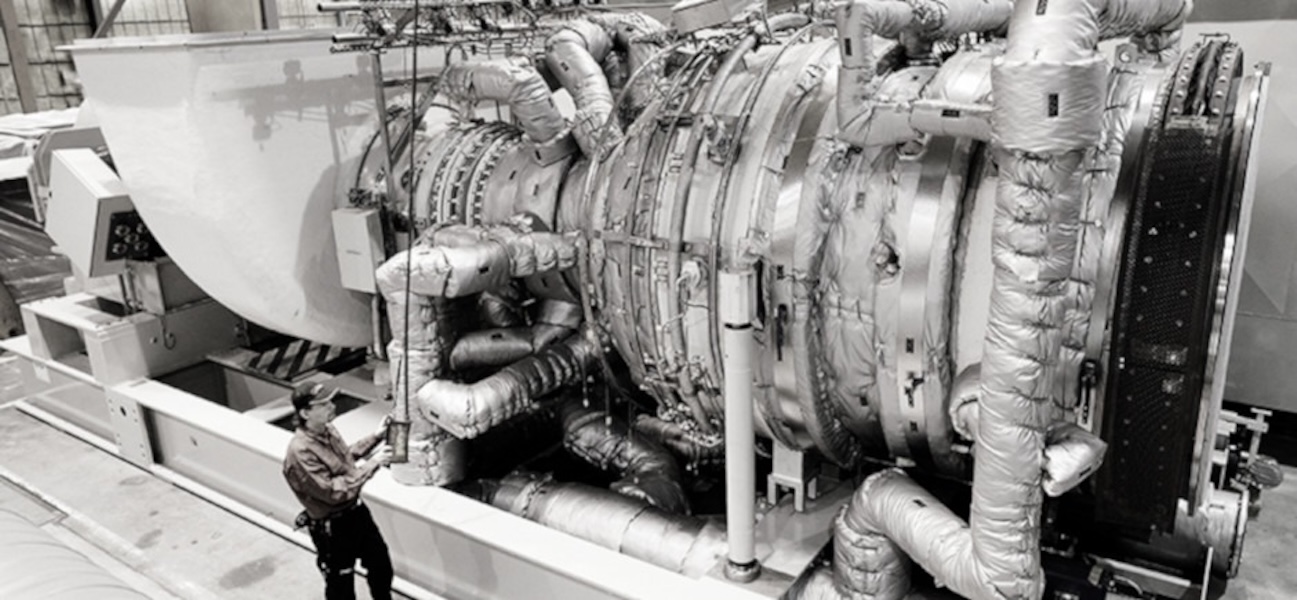

Turbines are extremely complex pieces of equipment. Each sits within a wider power plant solution which is tailored to each customer’s unique specifications and site conditions. The air intake assembly alone, for example, has 120 variants. Factor in all the configurations and combinations that come along with that; and things get complicated very quickly.

This complexity posed a challenge for Siemens Energy. Because the turbines are highly customized – and the combination of variables almost endless – producing customer quotes was a lengthy and complicated process.

A full customer proposal was often 500 pages long, took eight weeks to produce, and required specialist engineering help on almost every sales case.

The solution

The answer came in the form of configuration software from Tacton. Tacton’s technology redefines how products are configured – making it radically easier to design, configure and sell complex products.

With the Tacton CPQ, Siemens Energy quickly saw that they could streamline by creating pre-made assemblies, including standardizing much of the core turbine engine. Simplifying the product architecture in this way has reduced demands on engineering.

About Siemens Energy – a global leader in energy technology

Located in 90 countries, and with 98.000 employees Siemens Energy operates across the whole energy landscape. From conventional to renewable power, from grid technology to storage to electrifying complex industrial processes.

The mission is to support companies and countries with what they need to reduce greenhouse gas emissions and make energy reliable, affordable, and more sustainable.