Economic Uncertainty and Manufacturing Sales: How are Companies using CPQ to Stay Resilient?

Learn how CPQ is helping manufacturers create resilient manufacturing operations by streamlining the sale process and more!

CPQ and resilient manufacturing

Manufacturing sales are constantly changing, new products, and new customers make it important to stay on top of your sales pitch. These changes can create both challenges and opportunities for businesses, especially during uncertain economic times.

With uncertainty comes less customers and lower sales, making it critical to capitalize on every sales opportunity. Finding ways to create disruption-proof operations is the dream of every manufacturer, that’s why finding ways to build resilient operations is essential to that success.

Let’s look at the steps manufacturers can take to stay resilient and prepared to overcome any challenges that may arise now, or in the future.

What do we mean by resilient operations?

Resilient operations in manufacturing is the ability of manufacturers to quickly adapt to changing circumstances, recover from disruptions, and continue operations in the face of challenges. In recent years, the concept of resilience has become increasingly important in manufacturing as companies seek to improve their ability to deal with uncertainties and risks.

The COVID-19 pandemic was a wakeup call for many manufacturers. Shockwaves were felt across every aspect of the sales cycle from start to finish. That’s why so many manufacturers digital transformation efforts increased over the past few years. Now with many fearing a recession, manufacturers are still investing in their transformation goals.

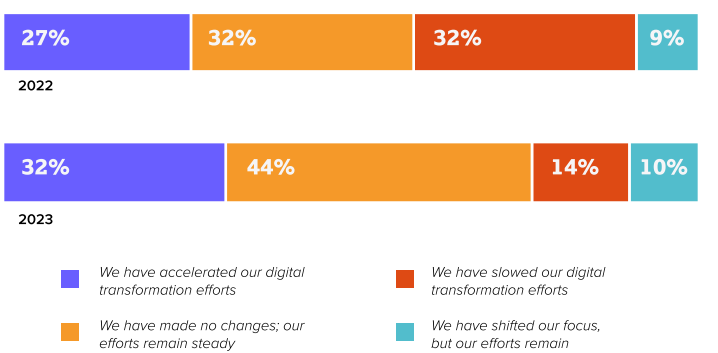

How has recent uncertain economic times impacted your digital transformation efforts?

How can manufacturers create resilient sales operations?

Manufacturers can create a resilient sales operation by implementing strategies that improve their ability to respond to changing market conditions, maintain customer satisfaction, and achieve long-term growth. These are a few strategies manufacturers can take to deal with these challenges:

Customer-centric approach:

A customer-centric approach involves focusing on the needs and preferences of customers and developing products and services that meet their needs. This approach requires manufacturers to gather and analyze customer feedback, develop customer profiles, and tailor their sales and marketing efforts to meet the needs of different customers.

Forward thinking manufacturers will also find ways to make it easier for customers to view their complete product portfolio online. Offering ways to view and possibly buy products online will help manufacturers create multiple touchpoints with customers instead of just one-to-one sales interactions.

Diversify sales channels:

Creating and optimizing different sales channels will be a key area for manufacturers to look into. This can involve developing a direct-to-consumer sales strategy, expanding into new markets, and establishing partnerships with other companies.

When manufacturers rely on a single source of revenue, they are more vulnerable to fluctuations in demand, supply chain disruptions, and other market forces. By diversifying their sales channels, manufacturers can reduce their reliance on a single source of revenue and spread their risk across multiple revenue streams.

Leading manufacturers are also beginning the process of selling subscriptions to their products. This development may still be in the early stages of reality but is becoming more likely as the years go on.

Gartner notes that by 2023, 20% of industrial equipment manufactures will support Equipment as a Service with remote industrial IoT capabilities.

Real-time sales analytics:

Real-time sales analytics provide manufacturers with up-to-date information on their sales performance, including sales volume, revenue, and profit margins. This visibility helps manufacturers to identify trends, monitor performance against targets, and adjust their sales strategies as needed to achieve their goals.

Bring sales reps up to speed faster:

A resilient sales operation requires a strong sales team that is knowledgeable, motivated, and customer focused. Manufacturers should invest in training and development programs for their sales teams to ensure that they have the skills and knowledge needed to succeed in today’s competitive market.

Manufacturers must also make sure they can do more with less. With an average time of 3.2 months for new sales reps to get up to speed it’s important to deploy tools that can lessen the time to value for your sales team.

When you free up your reps, they become more effective because they have more time to spend building impactful relationships with current customers, seeking new clients, and pursuing professional development.

Build strong partnerships:

Strong partnerships with distributors and other sales partners can help manufacturers to expand their market reach. By working with partners who have established relationships with customers in different regions or industries, manufacturers can access new markets and increase sales revenue.

The ability of different stakeholders within the manufacturing ecosystem, such as suppliers, customers, and partners, to work together towards a common goal. Collaboration can be achieved using open communication channels, shared data, and collaborative decision-making processes.

Risk Management:

Manufacturing companies should identify and assess potential risks, develop contingency plans, and regularly review and update their risk management strategies. Manufacturers must consider multiple areas when assessing their risks:

- Ensuring product quality

- Supply chain

- Compliance with regulations

- Financial interests

Supply Chain Management:

Manufacturers should develop robust supply chain strategies, diversify their supplier base, and implement real-time monitoring to detect and respond to supply chain disruptions. Ensuring timely delivery, and efficient resource usage will help manufacturers stay profitable, and flexible even with constant supply chain challenges.

Embrace digital technologies:

Digital technologies such as Configure, Price, Quote (CPQ) software can help manufacturers create a more efficient and effective sales operation. By leveraging digital technologies, manufacturers can streamline their sales processes, reduce costs, and improve their ability to reach and engage with customers.

How is CPQ helping create resilient sales for manufacturers?

CPQ is a software solution that can help manufacturers create resilient sales operations by streamlining the sales process and improving accuracy and speed in creating quotes and proposals. Here are some key take aways on how CPQ is helping leading manufacturers optimize the sales process:

Quicker turnaround times:

Sales teams need to have speed and accuracy to work with fresh leads. CPQ helps sales teams create 100% accurate quotes the first time, making the customer experience a smooth process.

Customized product offerings:

Providing a personalized and custom fit product to customers’ requirements has always been a challenge for high-variance products. CPQ makes it easier than ever to configure products to meet the needs of each customer.

Improved accuracy and consistency:

Manufactures lose money, work hours and customer loyalty with inconsistencies in their quoting process. CPQ reduces these costly miscommunications by providing accurate quotes every time.

Streamlined sales processes:

The sales process can move quickly with CPQ by automating the manual tasks that have bogged down sales and engineering in the past. Generating quotes and proposals complete with changes is a smooth process.

Better collaboration:

The slow back and forth between sales, product and engineering teams can be eliminated because CPQ only offers configurable products for customers. Sales reps won’t have to worry about selling products that aren’t feasible while engineering can focus on bigger projects and customers.

Improved forecasting:

CPQ provides real-time visibility into the sales pipeline, enabling manufacturers to better forecast demand and manage inventory levels.

Create resilient manufacturing operations with Tacton CPQ

Resilient manufacturing is a critical component of a successful manufacturing operation. By being flexible, agile, and collaborative, manufacturing companies can better respond to any challenge they face.

By implementing these strategies, manufacturing companies can achieve resilient operations that are better equipped to deal with the uncertainties of the modern business environment.

Tacton CPQ is helping leading manufacturers become resilient by providing speed and accuracy in their quoting process. This creates a fast and exciting way for your reps to sell products and leaves customers happier than ever because they don’t have to wait days for quotes anymore.

Chat with our experts to learn more about CPQ and resilient manufacturing!