Top Reasons Why Manufacturers Trust Tacton

Why Tacton? Manufacturers have trusted our CPQ for years, find out the top 9 reasons why in this short blog

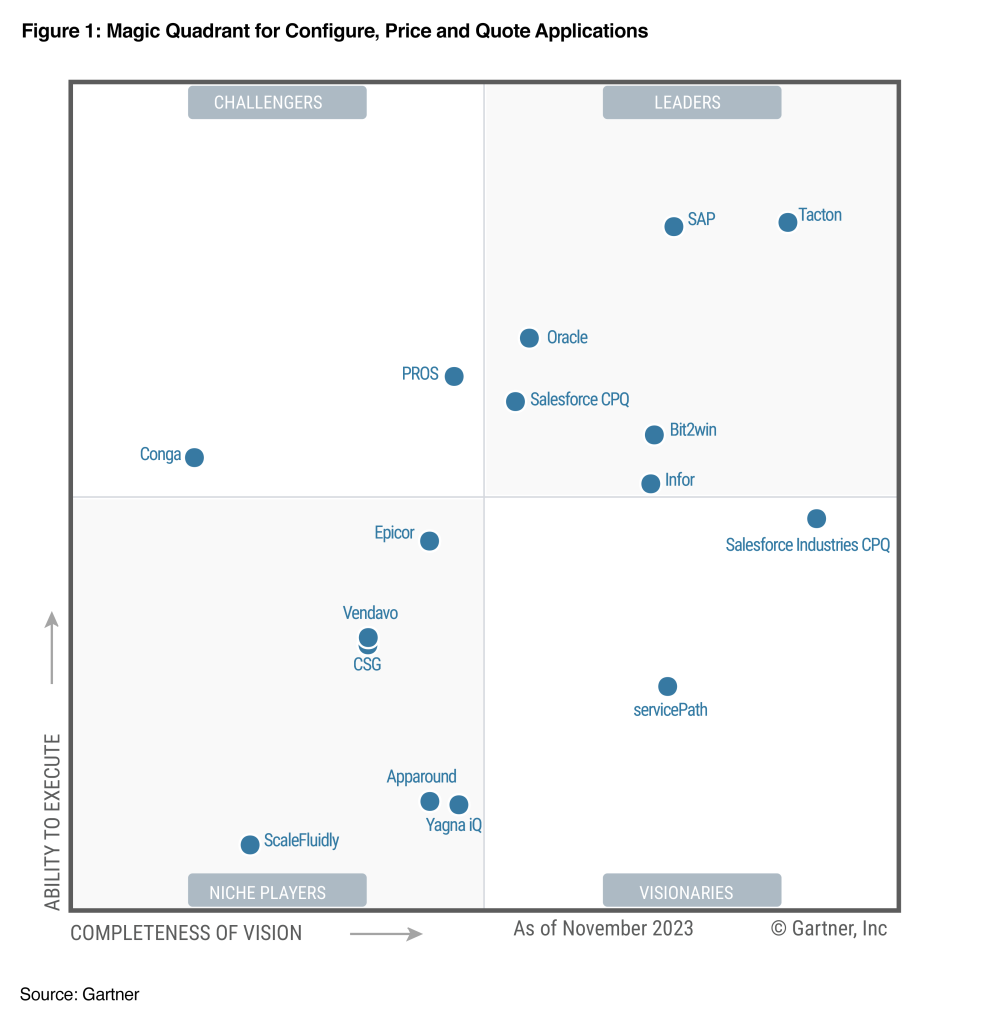

With a quarter century of successful innovation and growth validated by several years of recognition as a Leader in the 2023 Gartner® Magic Quadrant™ for Configure, Price and Quote Applications, many in the CPQ world ask:

What does Tacton offer that continues to build their partnerships with existing customers and drives new customers to select Tacton as a trusted partner?

To help answer this, let’s explore the top reasons why manufacturers choose Tacton:

1. Recognized Leader in CPQ, Validated by Industry Analysts

Tacton CPQ naturally stands out in the market, offering a comprehensive Configuration, Pricing, and Quoting (CPQ) solution that is both flexible and customer centric. This integrated approach is highly valued by customers for its low maintenance costs on a SaaS platform, centralized information for sales teams, and rapid time to value. Recognized by analysts such as Gartner® for its well architected platform and endorsed by users, Tacton is particularly recommended for complex manufacturing industries.

2. Tacton Lets Customers Focus on Revenue, Profitability and Quality and Not on Building a CPQ

With 25 years of experience, Tacton knows the nuances of manufacturing sales. Tacton CPQ is designed for quick deployment and ease of use with a configurable UI, sparing customers the effort of developing an in-house solution. Tacton’s industry-leading backend and customizable frontend, along with a robust API, facilitate the integration of existing systems, providing a comprehensive user experience without overhauling legacy systems.

3. Native Visualization to Manage Growing Customer Experience (CX) Needs

With most manufacturers focused on improving their customer experience and buying journey, Tacton sets itself apart with its native Visualization capabilities. Unlike many CPQ providers who rely on third-party suppliers, Tacton’s Visualization is developed in-house and seamlessly integrated with the CPQ system. This ensures that customers have a robust visual configuration tool right out of the box, enhancing the buying experience without the hassle of managing multiple vendors or integration challenges.

4. Purpose-Built for Scaling with High Performance

Tacton CPQ is designed for scalability and performance. By decoupling data from logic statements, Tacton makes system maintenance easier and more efficient, even with complex manufacturing setups. This methodology surpasses traditional rule-based setups, especially in handling extensive product options and configurations, thus avoiding performance degradation and high maintenance costs.

5. Unparalleled Configuration Technology

Tacton’s unique run-time constraints solver, developed specifically for manufacturing complexity, offers unmatched flexibility and ease of use. This technology, honed over 25 years, simplifies product offering setups and is key to successful CPQ implementations. Tacton employs rule-based configuration in limited, specific scenarios to ensure maximum adaptability for customers.

6. Platform Agnostic Integration

Tacton’s open API and extensive integration experience with CRM, ERP, PLM, and other tools ensure seamless connectivity with both new and legacy systems. This includes embedded integrations with Salesforce CRM and MS Dynamics. Tacton’s Data Import Automation further streamlines data updates from other systems, accommodating both on-premise and cloud setups.

7. A Full SaaS Offering Battle-Tested and Continuously Improved for Nearly a Decade

Tacton has been a trusted partner in the complex manufacturing sector for 25 years, offering a robust SaaS solution with multitenant functionality. This ensures seamless, secure, and low-maintenance data management on the cloud, with global reach and reliability.

8. Best in Industry for Administration/Maintenance of CPQ

Tacton’s unified interface for Product Modeling, Price Modeling, CAD Modeling, and CPQ Modeling simplifies the administration and maintenance of the system. This comprehensive approach significantly reduces maintenance costs and streamlines updates for new requirements, setting Tacton apart as a leader in CPQ solutions.

9. Unmatched Services and Support: The product reasons discussed above are a major reason for building trust but Tacton prides itself in the relationships built with customers. This trust is built by delivering the right type of expert implementation service and continued support in ensuring a successful outcome for manufacturers.

Get the full guide to Tacton Implementation here

In summary, Tacton’s CPQ solution offers a unique blend of innovation, integration, and intelligence, tailor-made for the complexities of the manufacturing sector. It stands out for its industry-validated leadership, native visualization, and focus on creating value rather than system building. Tacton’s purpose-built scalability, unparalleled configuration technology, and platform-agnostic integration are designed to meet both current and future needs of manufacturers. As a full SaaS offering, it ensures seamless, secure, and efficient operation globally.

Finally, Tacton is acclaimed for its exceptional ease of administration and maintenance, making it a top choice for manufacturing companies aiming to enhance their CPQ processes. We believe customers embrace Tacton to navigate the complexities of manufacturing sales with ease and efficiency, positioning their business at the forefront of technological advancement and customer satisfaction.

Want to learn more?