PLM and CPQ Integration: Why It Matters and How to Get It Right

Discover the many benefits of PLM and CPQ integration for sales efficiency and key considerations for planning your integration.

Rapid technological advancements and shifting customer expectations demand faster time-to-market than ever before. As a result, manufacturers need efficient ways to translate product and engineering data into sales-ready offerings. While product lifecycle management (PLM) systems maintain the latest product designs and specifications, turning that technical data into something sales teams can confidently quote remains a persistent challenge.

Integrating PLM and Configure, Price, Quote (CPQ) software creates a shared language between engineering and sales, ensuring teams work with the most current product information to easily bring accurate configurations to customers. To make the most effective use of these tools together, consider how the following benefits and best practices can help you solve your operational challenges both today and tomorrow.

CPQ Creates a Common Language Between Sales and Product Data

Your sales and engineering teams speak different languages. Sales structures offerings around customer needs and market requirements, while engineering defines them through technical specifications and manufacturing constraints within the PLM. It’s the CPQ that creates the common language and bridges the gap between engineering and sales.

Without PLM and CPQ integration, sales must manually interpret engineering data, risking misalignment between sales quotes and engineering bills of materials (BOMs). Alternatively, involving an engineer to support in the sales case occupies engineering resources and creates delays while waiting for an engineer to become available. This disconnect creates bottlenecks in bringing products to market.

Example: integration in elevator manufacturing

What does effective integration look like in practice?

Image a sales rep at an elevator manufacturer who needs to configure a solution for a high-rise building with specific weight capacity, speed, and safety requirements. With PLM-CPQ integration, they always work with the latest engineering rules and engineering-approved components—whether it’s an upgraded energy-efficient motor, a newly certified safety brake, or a redesigned control panel. If the customer requests a non-standard option, such as a custom cabin design or advanced energy-efficient features, sales can immediately trigger an engineering review within CPQ, getting faster approval without disrupting the sales cycle.

The Benefits of PLM and CPQ Integration Across the Value Chain

The seamless flow of product and sales data creates an impact across the business, from the customer experience to the relationship with suppliers.

1. Faster Order Processing and Shorter Lead Times

Complex product configurations often require extensive engineering validation, delaying the sales cycle. PLM-CPQ integration eliminates these bottlenecks by embedding engineering-approved configurations directly into the quoting process. This allows sales teams to generate accurate quotes instantly without waiting for manual reviews. Automated BOM creation further streamlines procurement and manufacturing, accelerating production timelines and improving on-time delivery.

2. Increased Engineering Efficiency and Innovation

Engineering teams often get bogged down with repetitive sales support, reviewing configurations to ensure manufacturability. By integrating PLM and CPQ, product rules are pre-validated, significantly reducing engineering workload. This frees up engineers to focus on strategic initiatives like product innovation, process improvements, and faster time-to-market for new offerings.

3. Enhanced Manufacturing Intelligence and Demand Forecasting

By linking sales configurations to real-time manufacturing data, businesses can anticipate demand more accurately and adjust production capacity proactively. Additionally, real-time CPQ insights into the most frequently configured products help engineers identify which features drive revenue and where to focus innovation.

4. Seamless Change Management and Data Integrity

Because product changes impact sales, procurement, and manufacturing, version control is essential. Connecting your PLM and CPQ guarantees that engineering updates automatically flow to sales tools, preventing discrepancies between what’s quoted and what can be built. If a customer requires something that is outside of the configurable option, sales can more easily request approval from engineering within the CPQ without additional back-and-forth.

5. Superior Customer Relationships and Higher Win Rates

Customer loyalty starts with the sales process. When sales and engineering work seamlessly, then sales can deliver error-free proposals that build trust from the start. That trust makes customers more likely to engage in long-term partnerships, opening the door for larger deals, expanded solutions, and future cross-sell or upsell opportunities.

6. Digital Self-Service and Omnichannel Enablement

Many manufacturers want to offer self-service quoting and configuration, but inconsistent pricing and configuration often lead to failed initiatives. PLM-CPQ integration guarantees that every selection—whether made by a salesperson, distributor, or partner—is valid and correctly priced. When sales teams and channel partners can generate error-free proposals with confidence, manufacturers create a strong foundation for scalable self-service applications, which can be a major differentiator in buyer engagement.

Integration Considerations for Maximizing Scalability and Sales Channel Flexibility

Integration is a strategic investment in efficiency, scalability, and customer experience. To fully realize its potential, manufacturers should consider how their integration strategy can scale and adapt to changing business objectives or customer demands.

- Balancing flexibility with control: Sales teams and customers want to configure products easily, but that flexibility can’t come at the expense of engineering accuracy. The best integrations embed engineering rules into the CPQ system, allowing self-service and guided selling experiences that are both flexible and constrained by manufacturability. This ensures customers can configure products without unknowingly creating issues downstream.

- Driving cross-departmental alignment: Integration success depends on collaboration between engineering, sales, IT, and operations. If the integration is designed without input from all stakeholders, it can either be too rigid (limiting sales) or too loose (causing engineering and production issues). A well-planned PLM and CPQ integration ensures everyone is working from the same product logic, reducing friction between departments.

- Adapting to evolving business models: The manufacturing industry is shifting toward mass customization, service selling, and self-service buying experiences. Without a scalable PLM-CPQ foundation, companies struggle to support these models without increasing complexity. A well-integrated system ensures tools can support everything from complex engineered-to-order (ETO) products to modular and subscription-based offerings.

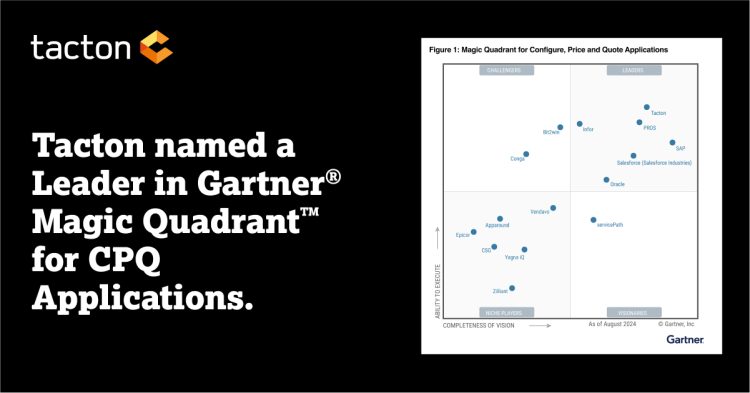

Boost Efficiency with Tacton’s CPQ Integrations

Integrating PLM and CPQ is a crucial step toward reducing inefficiencies and accelerating time-to-market. A well-connected digital thread ensures that product data flows seamlessly from engineering through sales and into production, eliminating costly misalignment and manual work.

Purpose-built for manufacturing, Tacton’s CPQ simplifies complex configurations and the quote-to-order process, while seamlessly integrating with your full tech stack. Tacton makes integration easy with both open APIs and a no-code integration framework: Connect-to-Anything, powered by Workato. Whether manufacturers need a fully customized integration or a plug-and-play approach, these options allow PLM, CPQ, ERP, and other critical systems to connect without complex IT projects.

By automating the flow of product data, Tacton ensures that customer needs are instantly translated into manufacturable configurations, quotes are optimized for both technical accuracy and competitiveness, and order fulfillment data is generated automatically to eliminate errors and delays. Manufacturers gain a fully integrated process that moves from configuration to production with accuracy and speed. Learn more about our solutions by scheduling a quick demo.