Generative AI Best Practices in Manufacturing: The Dos & Don’ts for Smarter Quote-to-Order

Manufacturers are eager to adopt generative AI, but many still struggle with trust, risk, and realistic expectations. These practical guidelines help manufacturers avoid risk and set realistic expectations.

Manufacturers are keen to embrace generative AI, including large language models (LLMs), despite the many lingering questions surrounding how it works and how to safeguard inherent risks. Will AI fix your problems? Can you trust it? How much can you automate safely?

In manufacturing, many of these questions surface first in sales and quote-to-order processes, where AI is increasingly used to speed up configuration, pricing, and decision-making. However, the implications reach beyond sales.

Generative AI in manufacturing is powerful, but not limitless. It accelerates strong systems and clean data, but it doesn’t repair broken processes or replace the contextual experience of human beings.

These generative AI best practices, illustrated through the manufacturing quote-to-order and CPQ process, will help you avoid common pitfalls and clarify what AI can and can’t do across your broader manufacturing organization.

Data quality best practices: accelerating structure with AI

AI, especially generative AI and natural language processing, process a large amount of information to develop outputs. It can do things like:

- Accelerate model building when structured data already exists (and, in some cases, it can turn unstructured data into structured data for you).

- Extract patterns from clean, consistent product documentation.

- Reduce manual effort once data foundations are in place.

However, it can’t fix poor data quality or missing product logic. It also can’t create a reliable output, such as a product model, from fragmented, conflicting, or inconsistent data.

Do

- Know where your data comes from: Identify which systems (PLM, ERP, PIM, spreadsheets, documents) are the source for product, pricing, and rules so AI isn’t trained on conflicting or unofficial data.

- Establish a single source of truth: Decide which system owns each type of data and ensure AI outputs map back to that authoritative model instead of creating parallel versions.

- Define the target structure before using AI: Use AI to extract and organize unstructured data only when attributes, allowed values, units, and rule logic are already defined.

- Use AI to surface gaps, not hide them: Treat missing attributes, unclear rules, and low-confidence outputs as signals that data needs refinement before scaling.

- Validate AI outputs against existing rules: Ensure AI-generated models, configurations, or quotes always pass configuration, compatibility, and pricing rules before customer use.

- Consider unit and regional consistency: Inconsistent units, currencies, or regional standards (metric vs imperial, local certifications) are common failure points.

Don’t

- Assume AI will resolve data ownership or consistency issues: AI cannot decide which source is correct when systems disagree.

- Treat extracted data as final: Information pulled from RFQs or documents must be normalized and mapped, not used verbatim.

- Skip validation because results look reasonable: Plausible outputs can still violate hidden constraints or edge cases.

- Don’t use edge cases and exceptions: AI performs best on standard cases. Rare exceptions should be clearly flagged or excluded.

If your data foundation is incomplete or poor, AI will only amplify the problem.

Transparency & oversight: generative AI can only assist

AI tools are incredibly powerful for suggesting models, product configurations, pricing, or predictive demand, but it can’t understand business context the way humans do. Though there is an opportunity for AI to eliminate unnecessary work, it shouldn’t be a replacement for experienced talent, but rather a tool to give them more time for strategy.

Do

- Make AI-generated outputs clearly visible: Users should always know what was generated or suggested by AI so they can review, question, and correct it.

- Keep humans in the loop, especially early on: Use expert review during initial rollouts to catch errors, build trust, and train the system before scaling.

- Provide confidence or accuracy indicators: Show how reliable an AI output is so users understand when extra scrutiny is needed.

- Surface where AI struggled or made assumptions: Flag missing data, ambiguities, or inferred values instead of hiding uncertainty.

Don’t

- Fully automate customer-facing decisions: Avoid letting AI finalize quotes, configurations, or recommendations without human review.

- Hide AI involvement: Presenting AI-generated outputs as human-created undermines trust and adoption.

- Treat AI outputs as authoritative without review: AI suggestions should be treated as drafts, not final answers.

AI can recommend, but only humans can take responsibility.

Implementation approach: Enabling focus

Generative AI in manufacturing speeds up repetitive, time-consuming tasks and supports internal teams by taking on the manual lift, so the business can scale. But it’s not something that can be globally adopted and scaled right away. It’s crucial to follow AI best practices that ensure your organization doesn’t jump the gun or act on unrealistic expectations.

Do

- Start with internal use cases first: Use AI internally (e.g., engineering support, RFQ processing, model preparation) to validate accuracy and workflows before exposing it to customers.

- Focus on narrow, well-defined problems: Apply AI to very specific tasks like data extraction, draft model creation, or parameter identification rather than broad, end-to-end processes.

- Pilot, measure, then expand: Test AI on a limited set of products, track accuracy and exceptions, and refine before scaling.

- Standardize inputs to improve results: Consistent formats, terminology, and schemas reduce ambiguity and increase AI reliability.

Don’t

- Treat Gen AI as a silver bullet: AI enhances existing processes but does not replace clear product logic, governance, or expertise. It can’t replace the knowledge that your teams possess around business context or commercial impact.

- Rush to customer-facing deployment: Exposing immature AI features risks errors, loss of trust, and rework.

- Expect near-perfect accuracy from day one: AI performance improves through iteration and refinement over time.

Security & governance: generative AI can be safe if used correctly

How do you process proprietary data without exposing it? Whether you’re using AI models you’ve built internally or using a third-party vendor, reading the fine print is one of the first steps in evaluating AI tools.

Do

- Use AI vendors with explicit data protection guarantees: Confirm contractually that your data remains private, isolated, and protected within your environment.

- Ensure data is not used to train public models: Verify that proprietary product, pricing, and customer data is excluded from any shared or external model training.

- Understand data flow and access points: Know exactly where data is ingested, processed, stored, and accessed across systems and AI components.

- Involve legal and IT teams early: Align security, compliance, and governance requirements before AI is deployed, not after.

Don’t

- Upload proprietary data into public AI tools: Public or consumer-grade AI platforms lack the controls required for sensitive manufacturing data.

- Assume all AI platforms follow the same standards: Security, isolation, and compliance vary widely between vendors and deployments.

- Skip governance discussions to move faster: Weak governance increases long-term risk and slows adoption when issues surface.

- Don’t treat AI-generated insights as exempt from compliance requirements: Outputs derived from regulated data may still fall under local laws, IP protection, or industry regulations.

Use case selection: prioritizing for early wins

There are hundreds of ways to use AI in manufacturing, but not every use case is necessary for your business. AI can solve specific problems, but it shouldn’t be adopted for the sake of building a technologically advanced operation.

Generative AI excels in a number of areas, including supporting guided selling workflows, building and defining products, analyzing performance data, etc. It can, however, be difficult to implement in high-risk processes.

Do

- Use Gen AI for acceleration, screening, and preparation: Let AI handle early-stage work like data extraction, draft models, or RFQ triage so experts can focus on decisions.

- Apply AI where expert knowledge already exists: AI performs best when it’s reinforcing documented rules or proven processes.

- Treat AI outputs as starting points, not final answers: Use AI to generate drafts that engineers, sales, or product experts refine and approve.

Don’t

- Deploy AI where errors have serious consequences: High-risk scenarios (safety, compliance, contractual commitments) require strict controls and review.

- Use AI without expert validation: AI cannot replace engineering or product judgment, especially in complex configurations.

- Don’t choose use cases with unclear ownership: If it’s unclear who reviews, approves, or corrects AI outputs, adoption will stall.

- Don’t pick use cases just because they sound impressive: Prioritize practical value over novelty.

Change management: augmenting your people

AI can be a powerful tool for faster onboarding and workflow acceleration. When your teams have the resources, training, and confidence they need, they’ll be more likely to adopt these tools.

Do

- Set realistic expectations about maturity and accuracy: Position Gen AI as an evolving capability that improves over time, not a finished or flawless solution.

- Communicate clearly what AI can and can’t do: Be explicit about where AI assists, what data and logic it’s working from, and where validation is required.

- Provide training and onboarding: Help users understand how to work with AI outputs and review them effectively.

- Address workforce concerns about replacement directly: Position AI as a tool that reduces manual effort and scales expertise, not one that replaces engineers, sales, or product experts.

- Listen to user feedback: Use real-world input to refine AI behavior, workflows, and trust over time.

Don’t

- Oversell AI capabilities: Overpromising erodes trust and increases resistance when reality doesn’t match expectations.

- Expect immediate perfection: Early errors are part of the learning process and should be planned for.

- Ignore adoption and change challenges: Successful AI deployment depends on people, incentives, and workflows, not just technology.

Continuous improvement: iterating through your evolution

AI will only continue to evolve, and if you’re working with AI-enabled tools, keeping up with new capabilities, regulations, and options is essential.

Do

- Monitor AI outputs continuously: Track accuracy, exceptions, and confidence levels to ensure AI behavior stays aligned with business and product rules.

- Analyze recurring errors: Look for patterns in mistakes to identify gaps in data, rules, or prompts that need refinement.

- Refine prompts, data, and rules over time: Adjust inputs and guardrails based on real usage rather than one-time setup.

- Iterate based on real-world usage: Let how users work with AI guide improvements and prioritization.

- Stay informed on evolving AI capabilities and regulations: Regularly reassess tools and practices as models, compliance requirements, and enterprise standards change.

Don’t

- Don’t position AI capabilities as static or “finished”: Messaging should reflect that AI evolves and improves, not that it’s fully complete.

- Don’t promise long-term behavior based on early results: Early performance does not guarantee future accuracy without ongoing refinement.

- Don’t reuse outdated AI messaging as capabilities change: Keep customer-facing and internal messaging aligned with current functionality.

- Don’t ignore regulatory or policy shifts: Compliance and governance expectations around AI will continue to evolve and must be reflected in both product behavior and messaging.

The most successful manufacturers know AI’s limits

Generative AI delivers real value when your data is ready, your use cases are focused, and humans remain accountable. Following AI best practices helps manufacturers avoid unnecessary risk while unlocking meaningful efficiency gains.

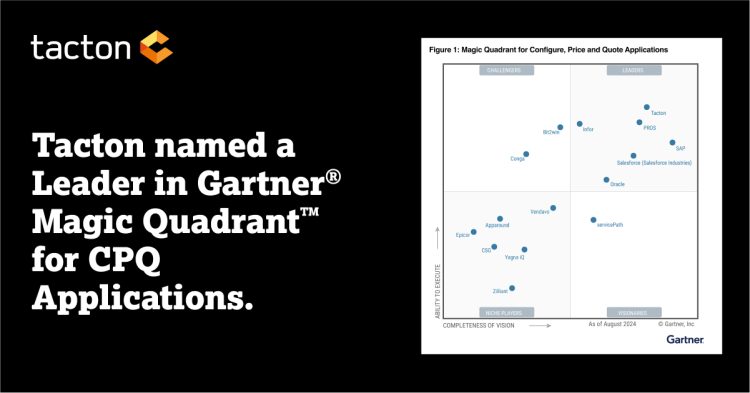

At Tacton, AI is built to strengthen your quote-to-order process. We integrate AI into our CPQ to help you accelerate RFQ-to-quote workflows, support product modeling, and validate configuration of highly complex products. AI works alongside your existing product logic and expert knowledge, not around it.

If you’re exploring AI, consider how AI can elevate your CPQ strategy, and how it fundamentally shifts how your teams deliver value.