The Connected Suite

Define, sell, and deliver complex products right, every time

Tacton connects Configure, Price, Quote (CPQ), Configuration Lifecycle Management, and Configured Order Fulfillment into one intelligent lifecycle so every sale is accurate, ready to build, and profitable to deliver.

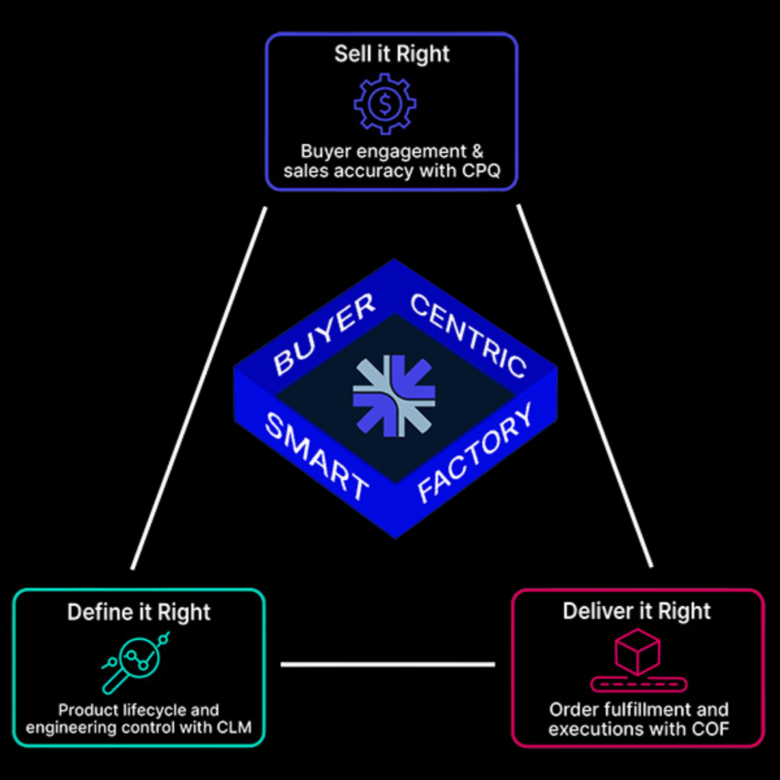

The Buyer-Centric Smart Factory

One digital thread from definition through delivery

When selling, engineering, and fulfillment operate in silos, errors and delays follow. Tacton connects configuration, product definition, and order fulfillment into one digital thread so customer commitments move from quote to production without friction or surprises.

An end-to-end manufacturing lifecycle platform

Configuration Lifecycle Management for product lifecycle and engineering control

Engineering governs product configurability in one source of truth. As products evolve, sales and fulfillment stay aligned to approved engineering intent.

CPQ for buyer engagement and sales accuracy

Sales teams and buyers configure complex products quickly using engineering-approved logic. Every quote is valid, consistent, and aligned with what can actually be built.

Configured Order Fulfillment for execution and profitability

Valid configurations become manufacturing-ready orders that remain in sync as requirements change, keeping production predictable and margins protected.

Innovation for Complex Manufacturing

Where buyer engagement meets the smart factory

Tacton brings together every part of the complex manufacturing lifecycle to create a connected, buyer-centric experience where what’s promised to the customer is always what’s delivered.

See how our platform strategy aligns buyer-led digital engagement with reliable execution across the entire lifecycle.

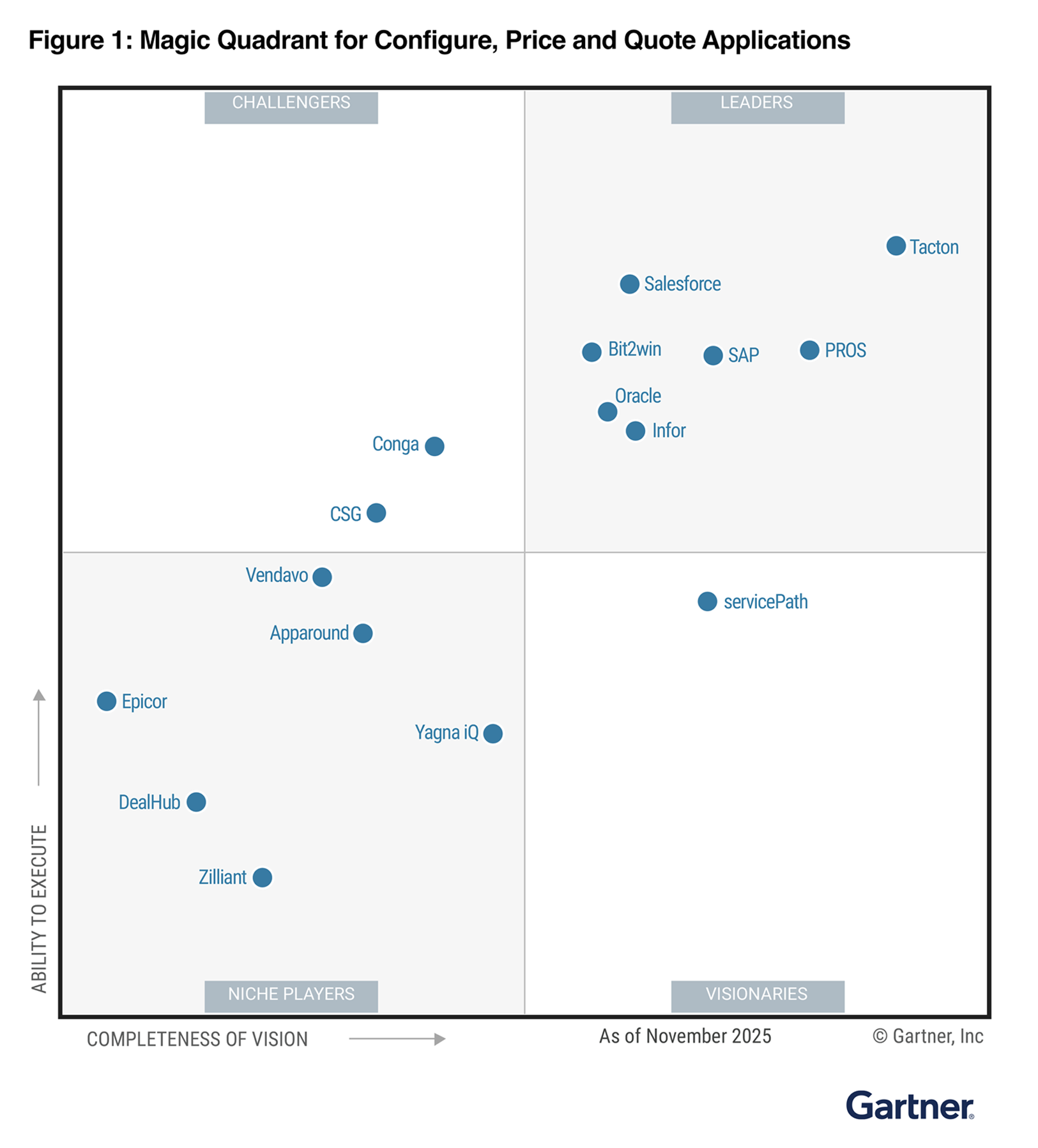

Recognitions

Tacton: A Gartner® Magic Quadrant™ Leader for CPQ Applications

See why Tacton was named a 4x Leader and positioned highest on the Ability to Execute and Completeness of Vision axes.

FAQs

The Buyer-Centric Smart Factory is a manufacturing model where the same product configuration logic is used and translated across sales, engineering, production, and service. This model creates one single source of truth that eliminates reinterpretation, rework, and margin erosion that impacts the speed and reliability that customers expect.

Instead of separate rules living in CPQ, PLM, ERP, or spreadsheets, the customer’s exact requirements flow through one shared configuration backbone. The quote is technically valid. The engineering design matches it. The manufacturing BOM reflects it. Service knows exactly what was delivered.