Configured Order Fulfillment

Turn sold configurations into build-ready, profitable orders

Control change orders and eliminate supply chain surprises by turning validated product configurations into accurate, production-ready orders.

Platform Overview

Close the gap between what is sold and what gets built

For manufacturers of complex, configurable products, risk does not end when a deal closes. Incomplete order data, late order changes, and misalignment between teams often lead to delays, rework, and margin erosion.

Tacton Configured Order Fulfillment (COF) creates a connected flow from sales to the shop floor by transforming validated configurations into accurate, manufacturing bill of materials. Every order reflects engineering intent and real factory capabilities, even when orders change.

Benefits

Execute complex orders with predictability and control

Deliver every order confidently

Ensure every sold configuration reaches production with complete, accurate, manufacturing-ready information even when orders change.

Protect margins from order to delivery

Reduce rework, delays and costly corrections knowing every order is manufacturable, properly routed and aligned with real factory capabilities.

Improve delivery predictability and reliability

Give production clear visibility into what is coming and when for realistic supply chain planning and on-time delivery.

Strengthen order change management

Understand the downstream impact of order changes so teams can respond without disrupting execution.

Align teams around a single order reality

Keep sales, engineering and production working from the same accurate order data to eliminate handoffs, confusion, and errors.

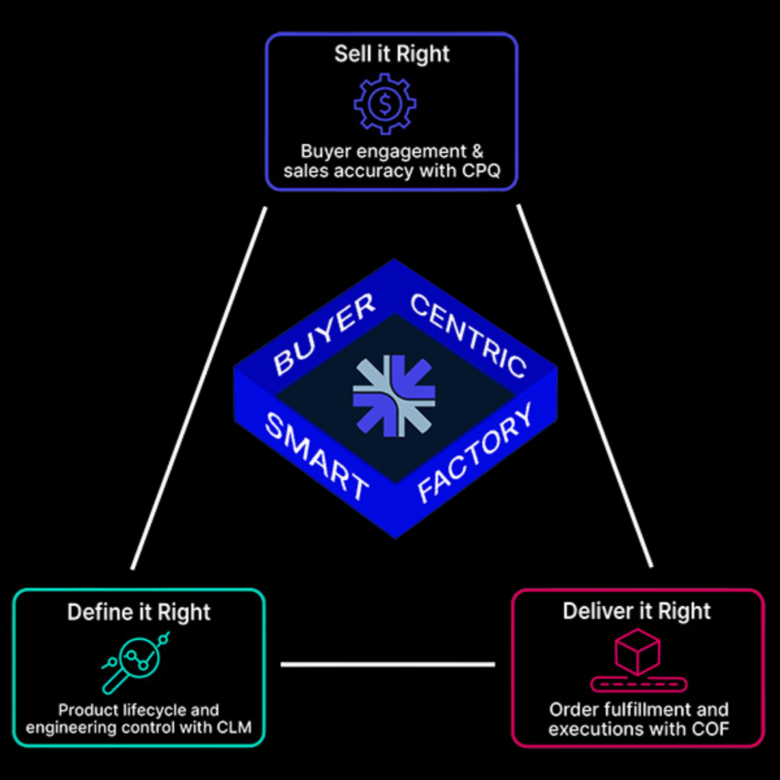

THE POWER OF THE CONNECTED SUITE

One digital thread across your manufacturing operations

CPQ ensures only valid solutions are sold. CLM governs what can be built and how products evolve. COF turns those decisions into accurate, build-ready orders.

Together, they create a single digital thread that connects what is sold, what is defined, and what is delivered, eliminating disconnects, reducing risk, and protecting margins at every stage.

Go Deeper

Building the Buyer-Centric Smart Factory

Tacton is evolving beyond CPQ to connect how complex products are discovered, configured, validated, and fulfilled across the entire lifecycle.

See how our platform strategy aligns buyer-led digital engagement with reliable execution, ensuring what is sold can be delivered accurately and profitably.

Recognitions

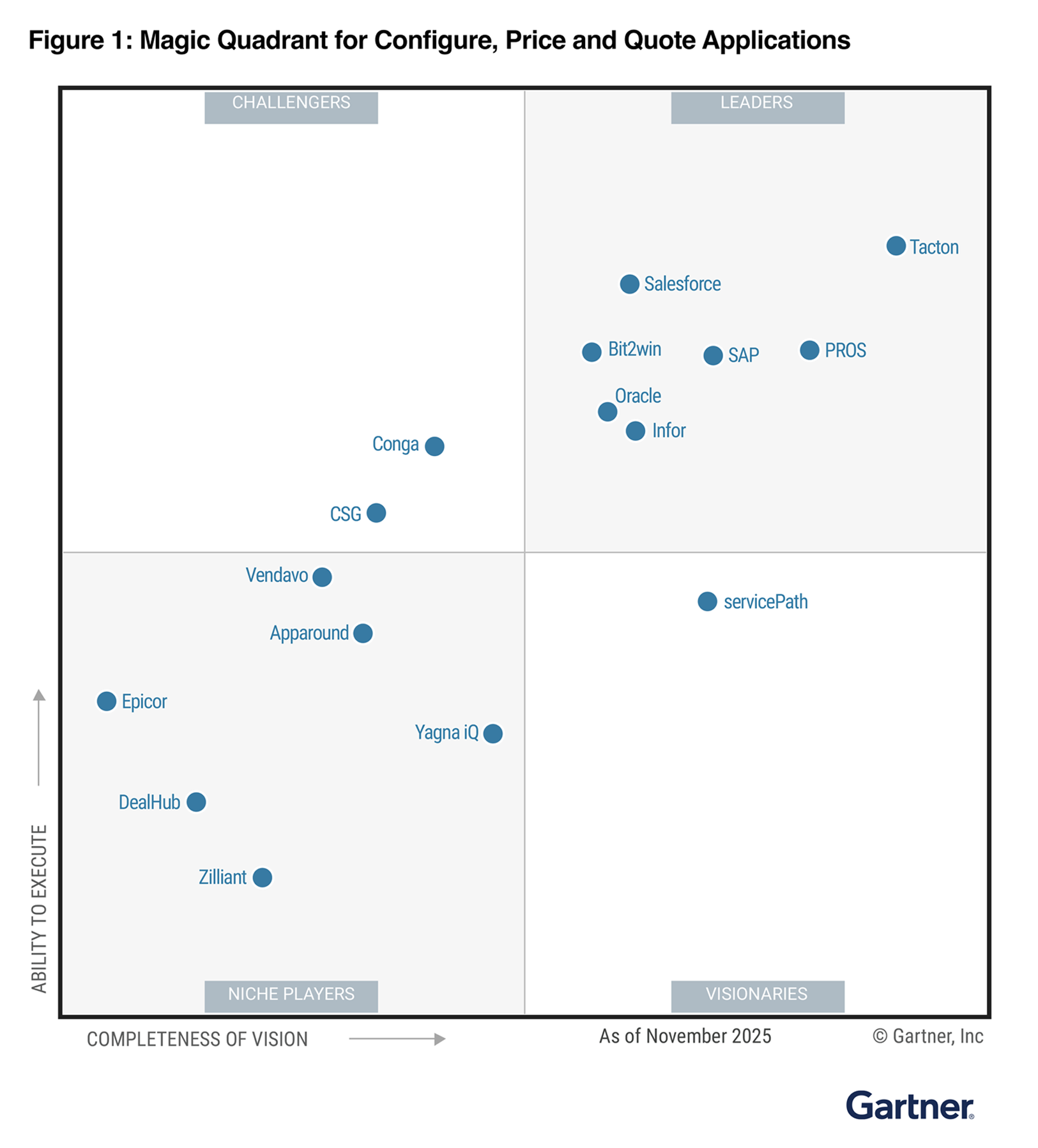

Tacton: A Gartner® Magic Quadrant™ Leader for CPQ Applications

See why Tacton was named a 4x Leader and positioned highest on the Ability to Execute and Completeness of Vision axes.