How Manufacturers Are Using AI to Drive Transformation: Insights from Over 200 Companies

Artificial intelligence (AI) has been a major pillar in the rise of smart manufacturing or Industry 4.0, including its use in digital twins and intelligent robotics on the production floor.

Artificial intelligence (AI) has been a major pillar in the rise of smart manufacturing or Industry 4.0, including its use in digital twins and intelligent robotics on the production floor. New data from over 200 manufacturers, however, shows that AI in the manufacturing industry is far from evenly leveraged, and foundational barriers make it difficult to use AI in ways that are both efficient and strategic across the value chain. However, leaders in AI adoption are getting a head start on the technology’s uses, not just in operations, but across the entire enterprise. They’re moving beyond siloed pilots to build more connected, data-driven businesses, laying the groundwork for transformation that reaches from production to sales.

Many Manufacturers Still Lag in AI Adoption

Currently, 48% of manufacturers are exploring potential AI uses cases for their business, according to an annual State of Manufacturing survey of over 200 global manufacturing companies that Tacton conducted in conjunction with Researchscape. However, only 16% of surveyed global manufacturers are currently heavily investing in the technology.

Where are manufacturers leading in the race to innovate, cut costs, and optimize their businesses with AI? And where are there opportunities to ensure AI is used not just as a production tool, but also as a strategic tool that brings innovation to the larger business model?

How Manufacturers Use AI: A Quick Guide to Common Use Cases

In order to understand how manufacturers are using—and not using—AI, it’s important to first understand that AI comes in many different forms. Basic forms of artificial intelligence have been used to increase efficiency for years, while newer types of AI are reshaping how companies think about their business models.

A few examples include:

- Expert systems: Around since the 70s, these AI models use rules-based, if-then type logic to help solve problems, like optimizing production with best practice logic or using rules to ensure valid product configuration.

- Machine learning and deep learning: Using deep pattern recognition and less explicit programming, these models solve much more complex problems in a way that’s similar to the human brain. Manufacturers use these models for predictive maintenance in equipment, predictive forecasting, guided selling, supply chain management, and more.

- Generative AI: Based on their given training data, these models generate new content for different scenarios. Often used for new product design, document creation, and other applications, this form of AI is evolving quickly.

While other forms and hybrid models exist, such as natural language processing and more visual forms of AI, today’s manufacturers still have significant room for adoption across their business functions. Despite the wide range of AI capabilities available, most manufacturers today focus their AI initiatives on fragmented sections of the value chain.

The AI Use Cases in Manufacturing that Businesses Are Exploring Today

With current economic constraints in the form of inflation, tariffs, and supply chain volatility, manufacturers are laser focused on how they make and deliver their product. That means limiting disruption and equipment downtime, streamlining the assembly line, and meeting demand profitably.

According to those surveyed:

- 19% of companies see the biggest AI opportunities in production line automation.

- 18% see major opportunities in supply chain optimization.

- 13% see major opportunity in predictive maintenance.

While 15% see generative AI for product design as a major opportunity, this is mostly concentrated in mid-market to enterprise businesses ($500M to $5B in revenue). Larger enterprises with over $5B in annual revenue tend to lag here, likely due to the friction of legacy systems and complex internal structures.

The Impact of AI Adoption

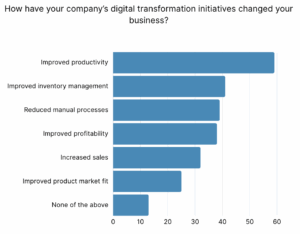

Companies already investing heavily in AI are more likely to see stronger business outcomes across the value chain from their digital transformations:

- 80% report improved productivity

- 66% cite improved inventory management

- 60% have increased sales

- 49% saw better product-market fit

Early adopters are also more likely to prioritize market expansion, sustainability, and customer experience to stay competitive, showing a more holistic approach to transformation.

Where Leaders Are Shifting Next: The Future of AI in Manufacturing

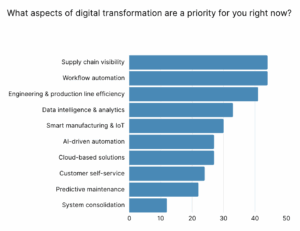

Today, much of the focus on AI in manufacturing is tactical and centered on cost reduction. Even for mid-market businesses who are more heavily investing in AI, the supply chain and production process is still king. But more mid-market players are investigating beyond factory efficiency towards value-add for their customers.

Some manufacturers are already using AI to improve how they bring products to market. They’re moving from production-centric use cases to customer-centric transformation and connecting buyer needs with production capabilities in real time.

Early adopters of AI, specifically those below $5B in annual revenue, are starting to explore more opportunities to use AI across their business and outside of the factory floor. In addition to interest in generative AI for product design and engineering, they’re also reporting more interest in AI for guided selling and smarter configuration in the sales process.

AI in CPQ: A Missed Opportunity?

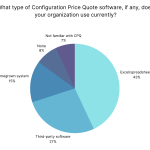

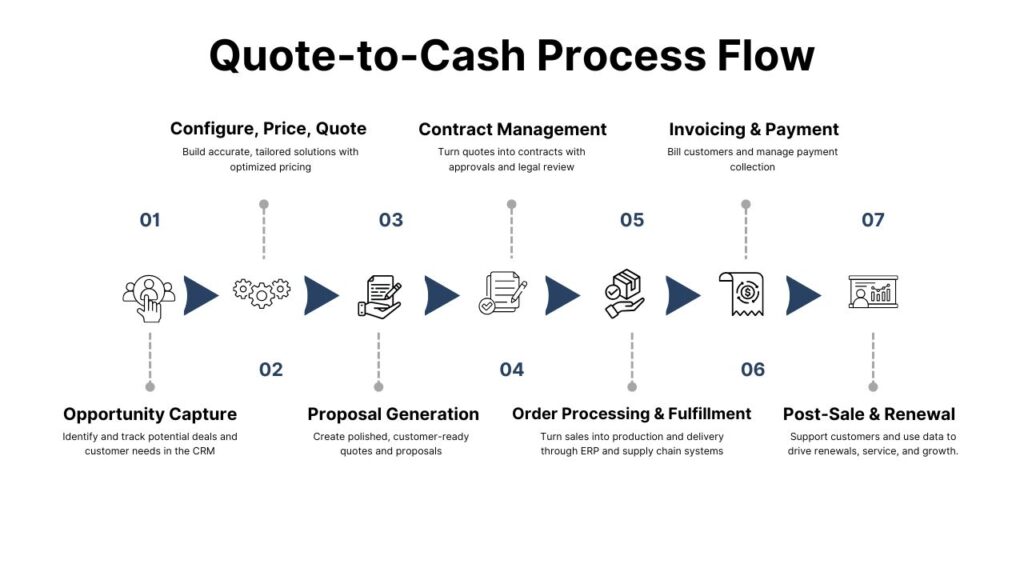

Only seven percent of manufacturers today see AI as an opportunity in guided selling or smarter configuration, despite the clear value. AI-enhanced CPQ (Configure, Price, Quote) platforms offer a powerful path forward, helping manufacturers and their customers:

- Automate complex configurations

- Guide non-technical buyers in configuration

- Reduce quoting errors

- Optimize pricing based on customer, cost, and sales data

- Enable dynamic recommendations at the point of sale

These aren’t just incremental improvements. They’re powered by AI models that continuously learn from quoting behavior, customer preferences, and sales outcomes. That makes AI in CPQ a major opportunity for scalable, data-driven customer engagement.

In addition, by integrating AI-driven CPQ with other operational systems, manufacturers will soon turn quote and configuration data into a strategic asset that drives predictive forecasts, adaptive product strategies, and intelligent pricing models. These capabilities are still emerging, but together, AI and CPQ can reshape how manufacturers sell, price, and innovate.

Early Adopters Have the Advantage

AI adopters have an opportunity to get a head start on the customer experience, where they understand that there is important value in remaining competitive at both the back end and in front of customers. Expanding customer channels, delivering more value at the point of sale, and creating a seamless, data-driven buyer journey will be the next areas where innovators and early adopters lead the industry.

Preparing for AI at Scale: What It Will Take

Manufacturers who continue to use AI only as a factory floor tool will hit diminishing returns. Sustained gains—higher margins, better customer retention—will come from connecting AI across the full customer journey.

But achieving a more strategic future requires a foundation that manufacturers are still building:

-

Clean, structured product and customer data

-

System integration across sales, engineering, and operations

-

Alignment between IT, sales, product, and executive leadership

Forward-thinking manufacturers are starting to make these investments. They recognize that scaling AI means thinking beyond automation to transform how products are sold, experienced, and delivered.

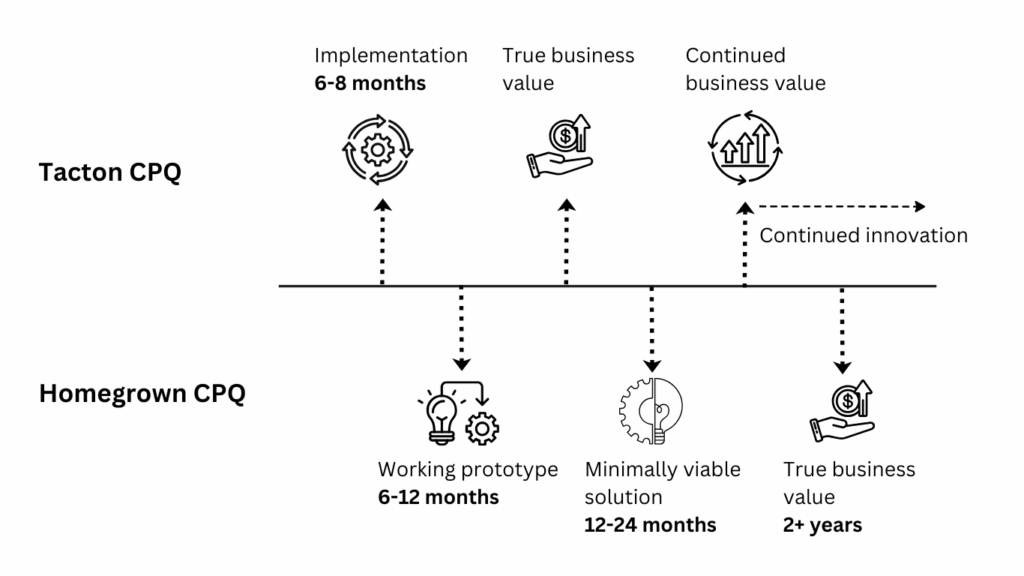

Tacton Brings Smarter Selling to Manufacturing

At Tacton, we help manufacturers move beyond traditional CPQ solutions to transform go-to-market efficiency and buyer engagement in one integrated platform. Our configuration, pricing optimization, embedded data, and guided selling solutions bring intelligence into the buyer journey, giving manufacturers the tools to sell and deliver complex products strategically.

Ready to connect your strategy to customer outcomes?