5 Pump and Fluid Handling Trends Driving Performance and Profitability

Pump and fluid handling manufacturers are rethinking efficiency through data connectivity, sustainability, and customer experience to drive smarter growth in the digital era.

Pump and fluid handling manufacturers are accelerating competitiveness through digital transformation. Advanced technologies, e-commerce-inspired buying experiences, and growing demand for energy efficiency are helping brands differentiate themselves, but ongoing trends reveal a common thread: connectivity. Pump manufacturers are linking data with predictability, sustainability with performance, and customers with real-time insight. These forces are catalyzing innovation and transforming go-to-market efficiency across the industry, and the way manufacturers will win is by bringing that same, efficient connectivity to their manufacturing lifecycle.

1. Adoption of digital twins in the pump & fluid handling market

The adoption of digital twins is changing how pumps and fluid systems are designed, sold, and serviced. A twin is a virtual replica of a pump or system that goes beyond CAD by integrating performance curves, materials, operating conditions, and live sensor feedback to mirror real-world behavior.

Adoption is accelerating as manufacturers link IoT data and physics-based simulation to improve reliability and predict maintenance. A recent collaboration between SPX FLOW and Siemens resulted in a digital twin of a mixing tank that uses CFD simulations, real-time industrial data, and flexible control modules. The collaboration demonstrates how virtual testing and optimization de-risk operations and speed improvement cycles for fluid processes that include pumps and valves.

For commercial teams, digital twins are becoming powerful selling tools. When integrated into configuration and quoting workflows, they allow every quote to double as a performance simulation that validates duty points and helps sales teams demonstrate measurable value. This capability also powers new business models ,such as performance guarantees and pay-per-use contracts, which are increasingly common in utilities and process industries.

A generational shift is amplifying this trend. The next wave of engineers and buyers—most of them digital natives—expect interactive product selection, 3D visualization, and instant feedback before engaging sales. Manufacturers that embed digital twin logic into their configuration tools and digital experiences stand out as more transparent and aligned with how modern buyers evaluate solutions.

2. Efficiency and sustainability as business drivers

As energy costs rise and environmental regulations tighten, pump and valve manufacturers are prioritizing efficiency as both an engineering and business imperative. According to the Hydraulic Institute, pump systems may account for up to 40% of industrial energy usage. Even a one- or two-percent gain in design efficiency can deliver enormous environmental and economic impact at scale.

Advances in fluid dynamics and additive manufacturing, for example, are enabling progress by reducing leakage or power demand while extending product lifespan. Buyers now expect verified sustainability documentation as part of every specification, and metrics like carbon data or lifecycle energy are no longer nice-to-haves in the quoting process.

3. Reliability, uptime, and the total cost of ownership mindset

Reliability has become a currency of trust, and it’s the highest pain point for buyers of industrial products, according to Accenture. Buyers are looking beyond purchase price to the true economics of uptime and lifecycle performance. Smart pumps equipped with self-diagnostics, remote monitoring, and predictive analytics are minimizing unplanned downtime and optimizing service schedules.

Manufacturers offering connected service models, where digital records and real-time insights support every installed asset, are using this to change their business model from product-focused to solution and outcome-focused. This evolution has made total cost of ownership (TCO) the metric that matters most in procurement, guiding decisions toward transparency and long-term value.

In effect, the most competitive suppliers are providing continuous assurance that every pump in operation performs as expected, with data and service woven into the customer experience. Services and predictive maintenance are also becoming part of the buying process, as manufacturers shift to outcome-based solutions, rather than products alone. But they’re also ensuring that customers get more transparency and reliability in lead times and delivery, as well, which requires a connected experience from sales to production.

4. Digital and e-commerce-driven procurement

Manufacturers and distributors are seeing double-digit growth in online sales channels as buyers increasingly adopt self-service quoting tools and digital comparison platforms. According to a recent study, e-commerce now represents approximately 13.4 % of total revenue in industrial distribution.

Platforms designed for spare parts and mid-tier assemblies are increasingly integrating with enterprise procurement systems, making ordering faster and more transparent. At the same time, digital commerce is reshaping how buyers expect to engage with manufacturers. For example, Xylem, a global pump and water technology company, now offers an online catalog and purchasing portal where customers can easily browse, configure, and order pumps or consumables directly. This growing trends reflects how industrial buyers are seeking the same immediacy and convenience they experience in consumer e-commerce.

5. The move toward modular systems

A growing trend in the fluid handling industry is the shift toward modular, configure-to-order systems. Manufacturers are increasingly offering modular pumps, configurable manifolds, and quick-connect assemblies that allow plants to reconfigure or scale operations with minimal disruption.

This modular approach supports agility in sectors such as pharmaceuticals, food processing, and semiconductors—industries where uptime and flexibility directly influence profitability. It shortens engineering cycles, simplifies maintenance, and reduces total lifecycle cost while improving responsiveness to fluctuating demand.

When combined with digital twins and connected service data, modular systems can be used to deliver more adaptive industrial performance.

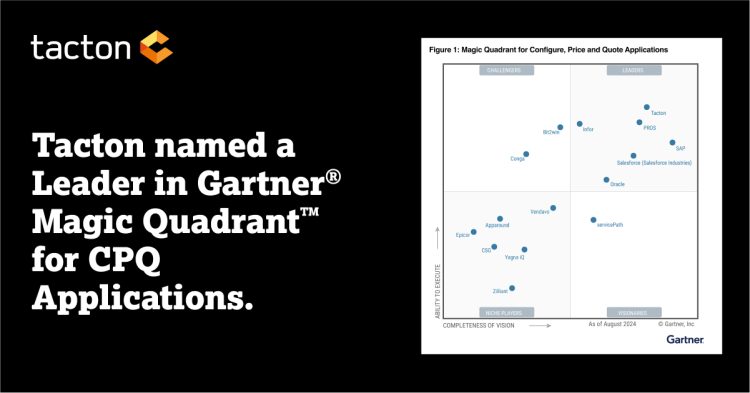

Maximize efficiency to stay ahead of the market: who is Tacton?

The pump and fluid handling industry is evolving toward connected, data-driven, and sustainable operations—and Tacton is helping manufacturers lead that change. Purpose-built for complex manufacturing, Tacton’s CPQ and lifecycle management solutions connect sales configuration, engineering, and fulfillment data to create a single source of truth.

Leading pump OEMs and distributors trust Tacton to streamline every step of the customer journey. Discover how Tacton helps pump manufacturers turn complex products into connected customer experiences.