Maximize margins with hybrid ETO and CTO solutions

Strike the right balance between engineer-to-order (ETO) and configure-to-order (CTO) processes with ETO manufacturing software built to cut time—but not control.

Deliver more products faster

Modularize your portfolio and minimize the number of ETO components in products to sharply reduce the time required to configure, price, and build them.

Build agility to better respond to customer needs

Lay the foundation for your buyer-centric smart factory with shared architecture, expert knowledge, and automated workflows.

Support solution selling

Gain the ability to implement full solution selling in a single flow, incorporating products, systems, spare parts, and services.

why tacton

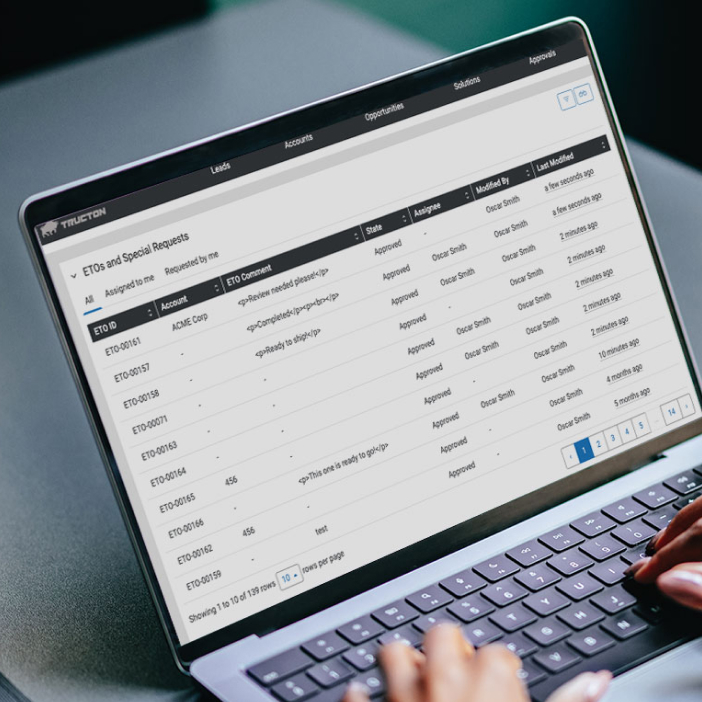

Get the tools needed to modernize your ETO manufacturing process

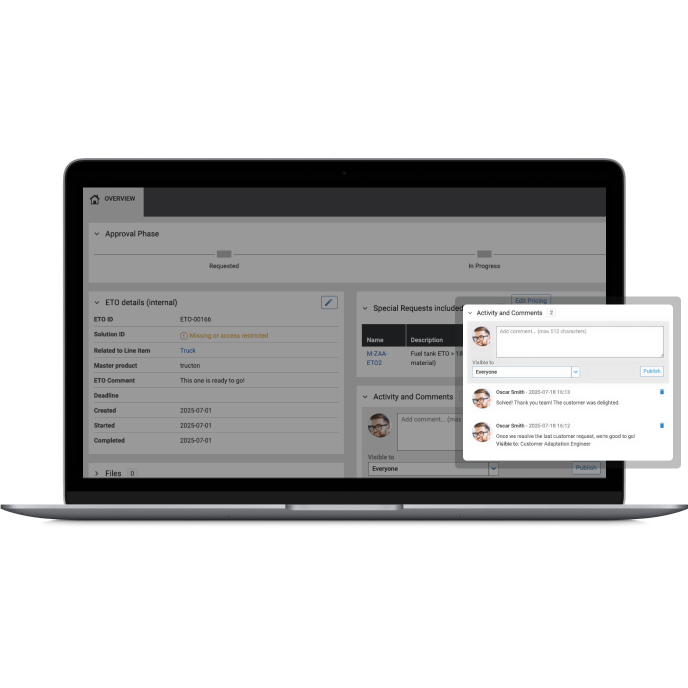

Hybrid ETO-CTO

Shifting from pure ETO to hybrid ETO-CTO products delivers higher margins in the short term, improves ETO process flow, and takes the first steps toward a customer-centric smart factory model.

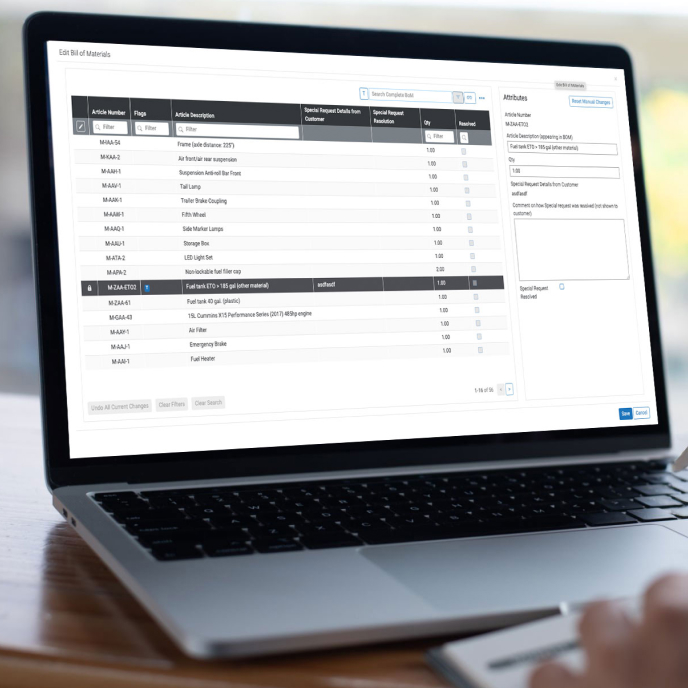

Modularize your product family

Capture product information and organize it into any number of configurable modules for hybrid ETO-CTO and full-CTO products.

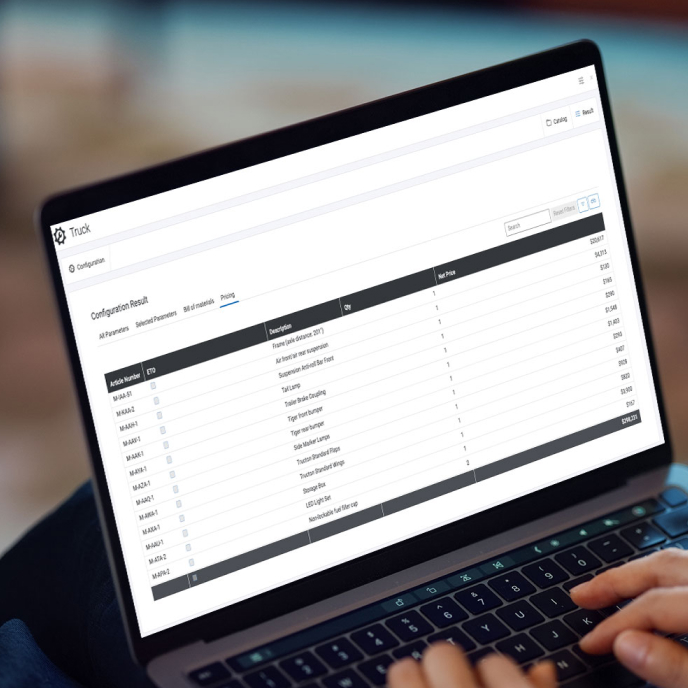

Automate process steps

Automate the configuration and pricing process step-by-step. You can build as much as possible from standard components and minimize ETO work.

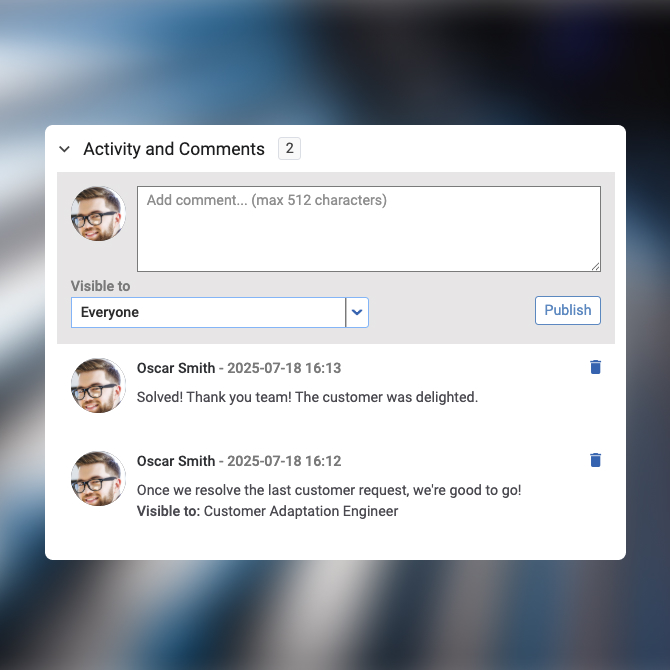

Capture and share expert knowledge to optimize your ETO-CTO workflows

Gather engineering know-how once and then scale it across teams, tools, and regions. Free up your engineers to focus on innovation and critical projects.

Take on more complex opportunities

With automatic configuration validation and optimization, you can increase the amount of CTO components in your products and give engineers more bandwidth to take on more complex ETO projects.

Integrations

Connect your enterprise tools seamlessly

Seamlessly integrate Tacton with your CRM, ERP, PLM, PIM, and analytics tools to unlock efficiency, eliminate silos, and ensure accurate, real-time data across the front and back end. Power faster decisions and streamlined workflows with a unified tech stack.

Success Stories