Leveraging Tacton System Configuration in Valve and Fluid Control Solutions

Tacton CPQ for valves and fluid control solutions makes it easier than ever to accurately quote, sell and meet your customers demands

Understanding Systems and Products

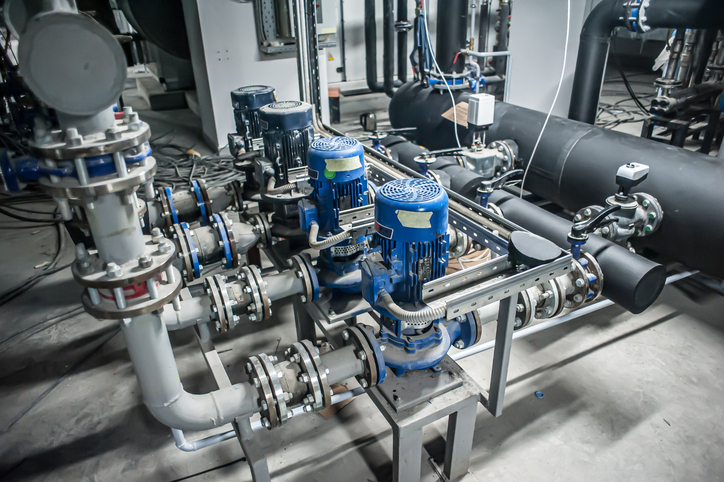

When discussing systems, the term often refers to complex assemblies or setups that encompass a range of interconnected components or processes. Unlike individual products, which tend to have a more fixed and defined architecture, systems are dynamic and can be configured in numerous ways based on user requirements. This distinction is crucial in industries like valve and fluid control solutions manufacturing, where the ability to configure custom solutions is paramount. These custom solutions can contain multiple interconnected systems of valves, and various other options that add to complexity.

The key characteristic of a system is its open-ended nature: when modeling a system, you have a multitude of configurable products that can vary in number and configuration based on the user’s needs. This flexibility means that changing one component of the system can impact other parts, highlighting the interrelationships and dependencies within the system.

The Need for System Configuration in Valve and Fluid Control Manufacturing

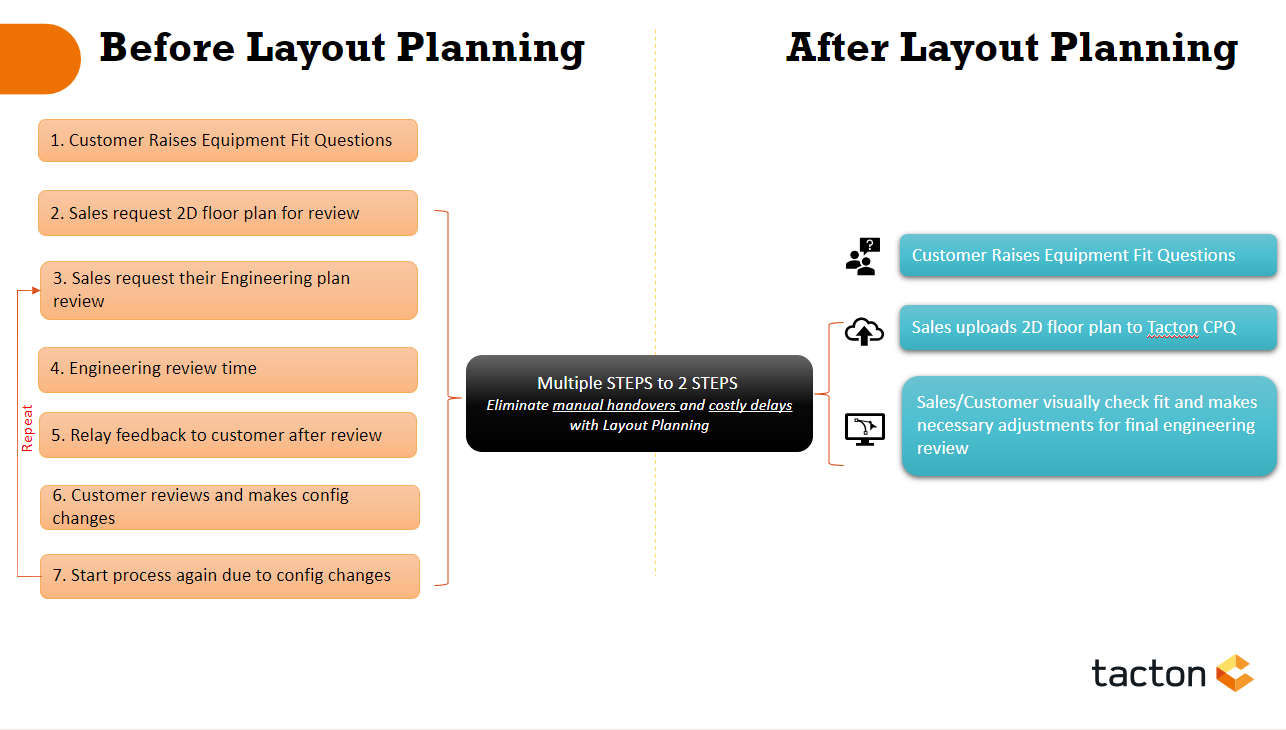

In the valve and fluid control manufacturing industry, traditional approaches often involve engineering-to-order (ETO) processes. ETO processes are inherently time-consuming and costly because they rely heavily on the expertise and input of product experts for each unique order. This approach can stifle innovation and slow down time to market, as each solution is essentially a one-off.

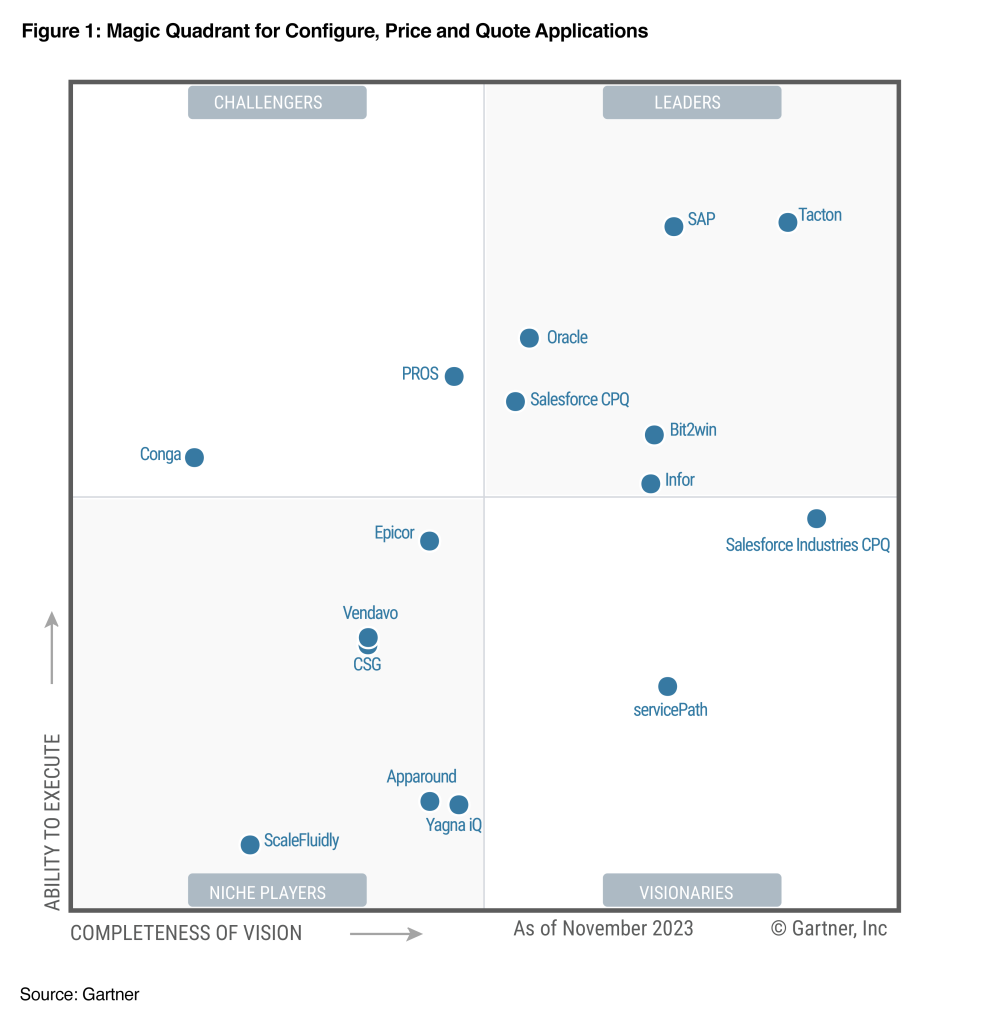

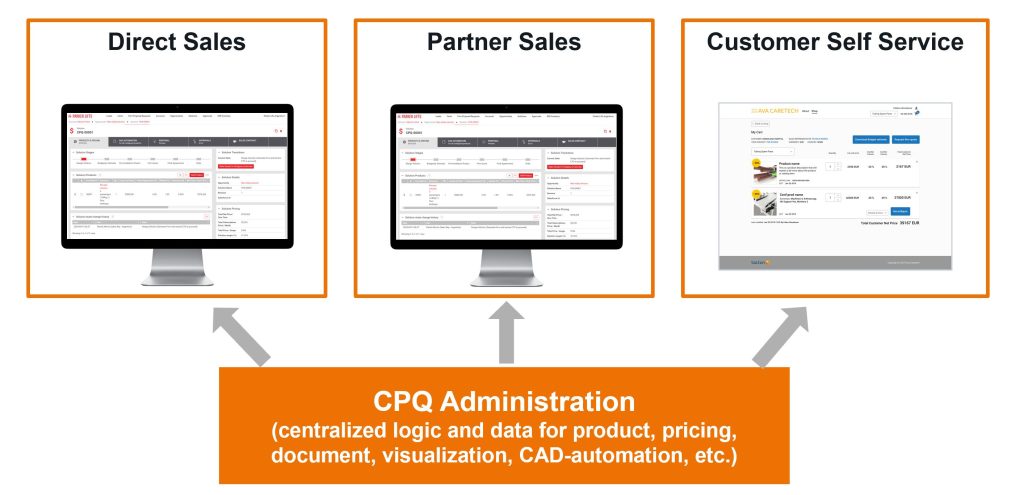

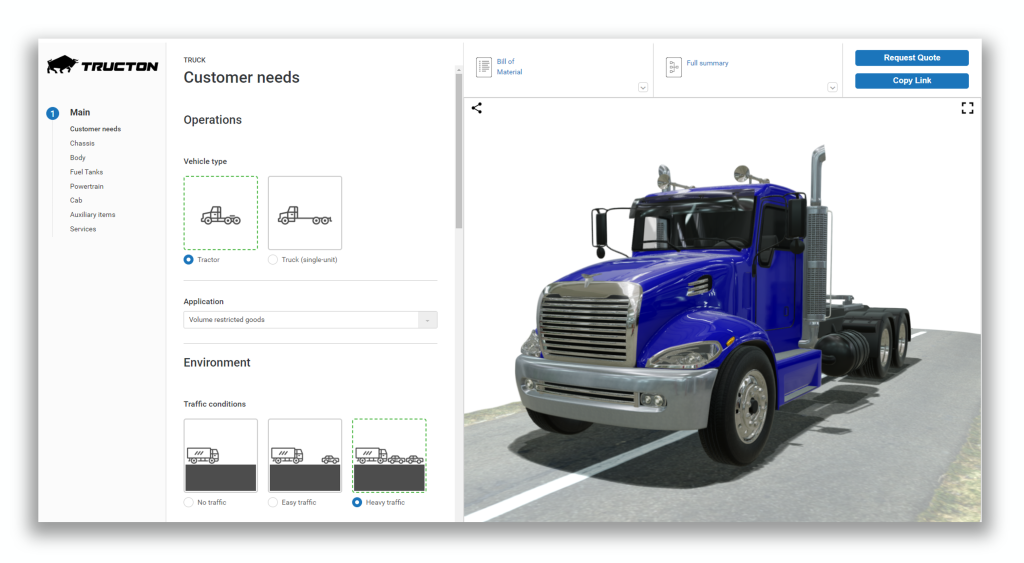

Tacton’s System Configuration aims to transition from ETO to configure-to-order (CTO). By leveraging Tacton’s configuration technology, valve manufacturers can manage a vast array of configurations, translating customer needs into technical solutions more efficiently. This shift not only reduces the reliance on product experts but also improves the overall quality, decreases lead times, and enhances the sales process.

Addressing System Configuration Challenges

While transitioning to a CTO model offers numerous benefits, it also presents challenges, particularly with large-scale system configurations. These challenges include defining the nature of the problem, managing performance issues, and handling open-ended configurations where the result is not fully known from the outset.

Tacton’s system configuration addresses these challenges by introducing complementary technology to their existing constraint-based configuration capabilities. This new approach allows for flexible rules and actions at the system level, making it possible to manage larger and more complex configurations without performance degradation.

Benefits for Stakeholders

The introduction of system configuration brings significant value to various stakeholders within a fluid control manufacturing organization:

- Product Managers: Easier introduction and maintenance of system configurations, allowing for more streamlined product definitions and a single source of truth.

- Modelers and CPQ Administrators: Simplified modeling of complex systems and improved tools for user interactions, enhancing the overall configuration process.

- Sales Representatives: Enhanced tools for selling systems, enabling quick responses to customer inquiries and reducing the need for backend involvement in all quotes.

Business Value of System Configuration

For the organization, system configuration offers numerous benefits:

- Increased Sales Efficiency: By moving a larger portion of the portfolio to CTO, errors are reduced, and the sales process becomes more efficient.

- Faster Quote Creation: Quicker and more accurate quote generation, leading to faster time to value and increased revenue.

- Reduced Customization Risk: Minimizing the need for custom solutions, reducing complexity, and focusing on standardized configurations.

Tacton’s System Configuration in Action

Tacton’s system configuration approach involves a two-layer model: the bottom layer consists of individual constraint-based problems (e.g., specific machines or components in a production line), while the top layer represents a network of nodes, each connected by rules and actions. This structure allows for flexible and scalable configurations.

For example, in a valve manufacturing setup, each machine or component can be configured as a node with specific attributes and connections to other nodes. This setup enables the creation of comprehensive and dynamic solutions tailored to specific customer requirements.

In closing

By leveraging Tacton’s system configuration technology, valve manufacturers can overcome the limitations of traditional ETO processes and embrace a more efficient and scalable CTO model. This transition not only enhances the sales process and reduces costs but also fosters innovation and faster time to market. With Tacton’s advanced configuration capabilities, valve manufacturers can confidently tackle the complexities of large-scale system configurations, ultimately driving business growth and customer satisfaction.