Many customers have a need to optimize the available floor space before placing an order for equipment or systems. One critical aspect of this optimization is layout planning, which involves designing the most efficient arrangement of machines, workstations, and resources within a manufacturing facility or industrial environment.

Having a well-organized environment is crucial for achieving success, and any inaccuracies can result in significant costs for customers. That’s why more customers are making large efforts to create a perfectly optimized space.

That’s all changing with Tacton’s Layout Planning, an exciting new approach combining Configure, Price, Quote (CPQ) and Visual Configuration, manufacturers are now able to empower their sales reps to quote large scale systems faster and increase win rates by providing visuals that fit directly into customers floor layouts. Let’s take a deep dive into Tacton Layout Planning.

What are common challenges manufacturers face when selling large scale systems?

Manufacturers have been struggling to keep up with customer demands. This is especially true when it comes to selling products that need to fit into specific plant floor layouts. The quoting process is often full of errors, bottlenecks and incorrect data that lead to misquoting, delays and ultimately disappointed customers.

What is Layout Planning?

Layout Planning is a tool that simplifies customers understanding of how a machine or system will fit on their plant floor. During the quoting process sales reps can place and arrange the whole system configuration or individual machinery directly in the floor plan provided by a prospect or customer. By providing this visualization to customers it helps support their choices by providing layout plans to the corresponding configuration.

What does the process look like without Tacton Layout Planning?

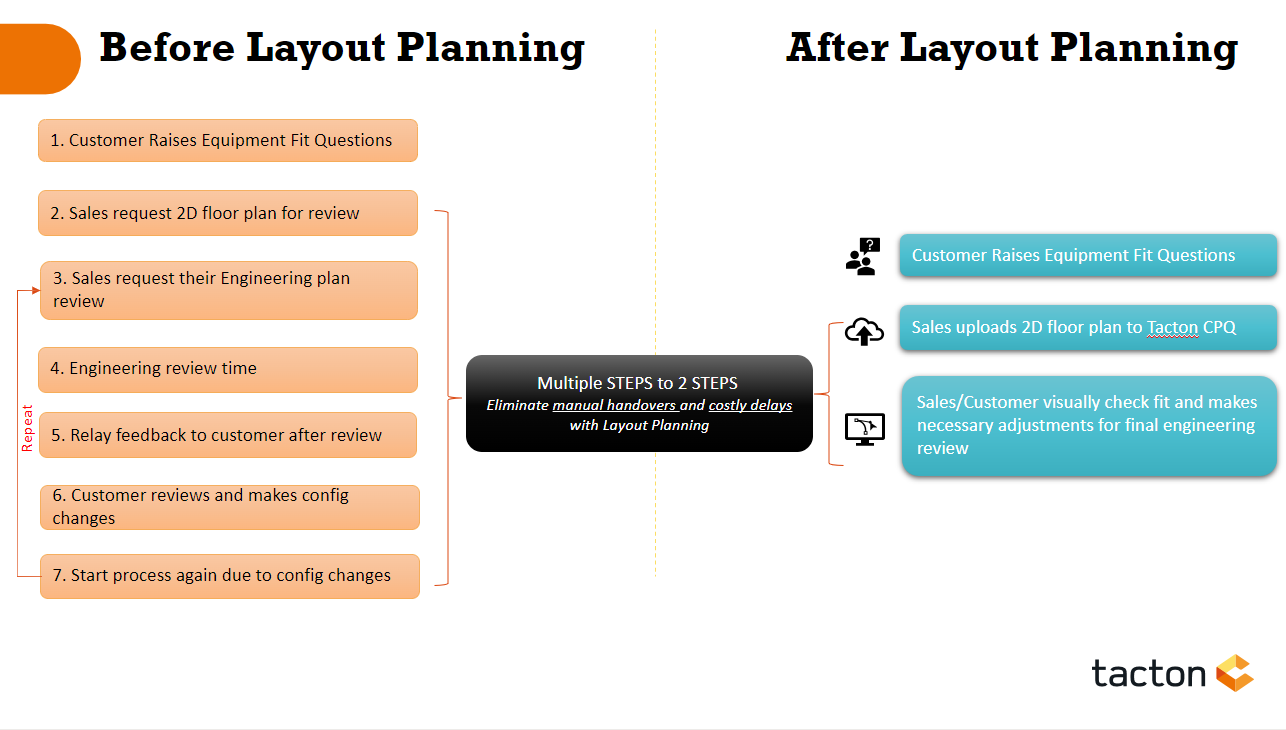

In the not-so-distant past, manufacturers and their customers faced a series of challenges when it came to planning and configuring equipment layouts. The process went something like this:

- Customer Needs: Customers often had concerns about how the manufacturer’s equipment would physically fit into their facility. Questions about space requirements and compatibility were common.

- 2D Floor Plans: Sales representatives would then request 2D floor plans from customers to facilitate engineering reviews. This step aimed to ensure that the equipment could be accommodated within the available space.

- Engineering Review: The customer-provided 2D drawings were sent to the engineering team for review. Engineers would scrutinize the plans for any potential conflicts or constraints.

- Engineer Feedback: After the engineering review, feedback will be relayed back to the sales reps. This feedback could involve necessary adjustments or even limitations on the equipment’s placement.

- Customer Feedback Loop: If changes were needed, the process repeated, causing significant delays. These delays presented opportunities for competitors to jump in and provide quotes faster.

What was quoting like before and after Layout Planning?

How is the sales cycle expedited with Layout Planning?

Faster Quotation Process

Users of Layout Planning can significantly speed up the quotation process by reducing manual handovers and providing visual layout feedback to customers, leading to higher win rates.

Visualization

One of the most significant advantages of Layout Planning is the ability to visualize equipment placement in 3D. This enhances understanding, as stakeholders can see exactly how the equipment fits within their facility.

Layout Planning extends Tacton’s existing visual configuration capabilities, empowering CPQ users to position and orient components of the configuration visually through simple drag-and-drop actions.

No CAD expertise or other software needed

Layout Planning allows sales representatives to create a visual layout of equipment and systems while adjusting configurations without additional CAD software or engineering involvement.

Streamlining Communication

Layout Planning with CPQ bridges the communication gap between customers, sales representatives, and engineers. Instead of relying on 2D floor plans and back-and-forth emails, CPQ and Layout Configuration provide a way to share quotes that both the sales reps and customers can trust.

Flexibility

If changes are required, it’s fast and easy to adjust. Customers can see the impact of alterations immediately, ensuring a more dynamic and responsive planning process. Users can adjust configurations to specific spatial needs and requirements, whether unconstrained, in pre-defined positions, or based on uploaded 2D floor plans of existing buildings and environments.

Competitive Edge

With streamlined processes, manufacturers can provide quotes faster and with greater accuracy. This minimizes the window of opportunity for competitors and enhances the manufacturer’s standing in the eyes of the customer.

Enhanced Customer Experience

Efficient layout planning translates into a smoother customer experience. Customers appreciate the responsiveness and precision that layout planning brings to the table.

In closing

Today’s market is increasingly competitive, this makes optimizing efficiency paramount. Traditional methods often lead to inaccuracies, delays, and customer dissatisfaction, creating significant challenges for manufacturers.

Tacton’s Layout Planning, is a game-changer. It empowers sales reps to quote individualized equipment or large-scale systems faster working alongside the customer. By providing customers with visuals that align perfectly with their real-world spaces, Tacton Layout Planning addresses the common challenges manufacturers face when selling complex systems.

In a world where success is often determined by speed, accuracy, and customer satisfaction, Tacton Layout Planning is a powerful tool that is reshaping the manufacturing landscape and setting new standards for industrial efficiency. It empowers manufacturers to meet customer demands with confidence and agility, ensuring they remain competitive in a rapidly evolving market.

Learn more in our video on Layout Planning!:

Interested in learning more? Schedule your call with us today!