Blog

Constraint-Based vs. Rules-Based Configuration: The Advantage for Complex Manufacturing

When configuring products with thousands of parts, variants, and customer-specific requirements, constraint-based configuration offers the flexibility, scalability, and resilience that rule-based configuration engines simply can’t match.

5 Metrics You Should Track to Measure CPQ ROI and Adoption

To measure configure, price, quote (CPQ) ROI accurately, manufacturers must look beyond KPIs like quote volume or deal revenue and include internal user metrics, or CPQ performance metrics.

Traditional CPQ vs. Buyer Engagement Platform: What It Means and Why It Matters

As sales cycles lengthen and digital buyers drop off at the first sign of friction. Buyers now need more guidance, support, and understanding of their business goals beyond what the current configure, price, quote (CPQ) process provides.

How to Evaluate CPQ Vendors: RFP Checklist and Key Evaluation Criteria

With so many software solutions available, choosing the right configure, price, quote (CPQ) software is a high-stakes decision for manufacturers looking to maximize ROI and minimize risk.

How to Build a Business Case for CPQ That Drives Strategic Impact

Manufacturers are accelerating digital transformation, but for IT and transformation leaders, securing executive buy-in for new technology remains a challenge amid competing priorities and tight budgets.

CPQ Software for Complex Products: Is It Right for Your Business?

When you sell complex products with hundreds or thousands of variants, quoting becomes a high-stakes process.

What Is CPQ for Manufacturing? A Complete Guide

The first one to solve a prospect’s problem becomes the partner of choice. If you’re wrestling with pricing and product SKUs in multiple places, if quoting takes weeks of technical validation, or if you’re reworking and adjusting quotes consistently, then you’re losing potential business.

8 Benefits of CPQ Software for Complex Products

In manufacturing today, 43% of businesses rely on Excel for complex quoting, and 51% require engineering involvement for most quotes. One small error can trigger rework and lost revenue. It’s slow, risky, and inefficient, but it’s familiar.

Overcoming CPQ Implementation Challenges: Common Pitfalls and Frameworks for Success

Despite growing pressure to improve the customer experience with speed and accuracy, many manufacturers still rely on manual quoting, static catalogs, and siloed systems that slow down sales and introduce costly errors.

Improving Speed-to-Market in Medtech Sales: How Quoting Automation Transformed a Manufacturer’s Operations

Conf Industries, an Italian manufacturer of customizable hospital logistics equipment, saw a clear opportunity. Sales were strong, and demand for customized products was growing, but quoting was hindering speed-to-market. Each custom request triggered engineering reviews, manual BOM creation, and back-and-forth with sales. A simple caster swap could delay an order by days.

The New Rules of Pricing Strategy in Complex B2B Manufacturing

Rising costs are forcing manufacturers to make tougher decisions about how they price. Materials, energy, and labor expenses continue to climb, with limited room to pass those increases on. And when pricing execution breaks down, it puts deals and margins at risk.

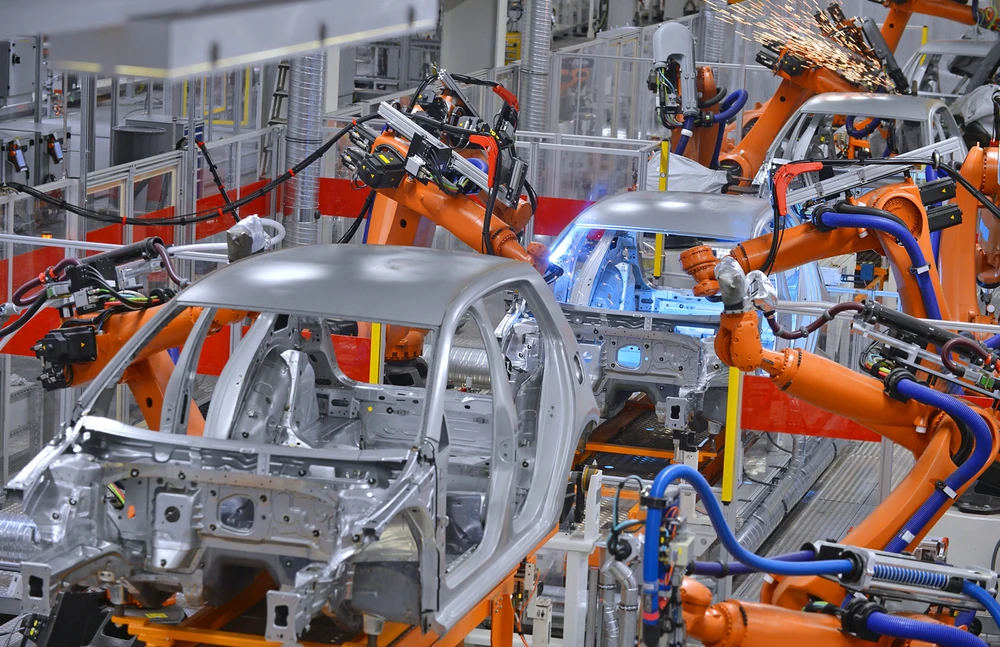

How Manufacturers Are Using AI to Drive Transformation: Insights from Over 200 Companies

Artificial intelligence (AI) has been a major pillar in the rise of smart manufacturing or Industry 4.0, including its use in digital twins and intelligent robotics on the production floor.