How Piab Scaled Modular Engineering and Powers 40K+ Self-Service Configurations Each Month

The company

A global manufacturer in vacuum automation and lifting solutions

Piab is a global leader in vacuum automation and lifting solutions, helping manufacturers improve productivity, energy efficiency, and workplace safety across automotive, electronics, food, pharma, logistics, and packaging. Piab operates in over 20 countries with a portfolio spanning vacuum pumps, conveyors, suction cups, and robot end-of-arm tools.

The Challenge

Scaling a modular product strategy

Piab’s portfolio is inherently modular: hundreds of suction cups, fittings, and filters can be combined into custom vacuum systems for any factory environment. However, this complexity was managed through a number of web tools and configurators, making it difficult to keep data consistent across systems, equip distributors and customers to build solutions independently, and link configuration logic with real-time pricing, availability, and ERP data.

As Piab expanded globally, it needed to digitally scale its modular product strategy for customers, partners, and internal teams to configure and purchase standard components online.

The Solution

Building a fully integrated digital system

Piab decided to power its Customer Self-Service (CSS) platform through Tacton’s CPQ, creating a unified configuration and commerce experience for both internal users and external customers. This turned Piab’s long-standing expertise in modular design into a fully integrated digital system by linking product configuration, pricing, visualization, and ERP synchronization.

-

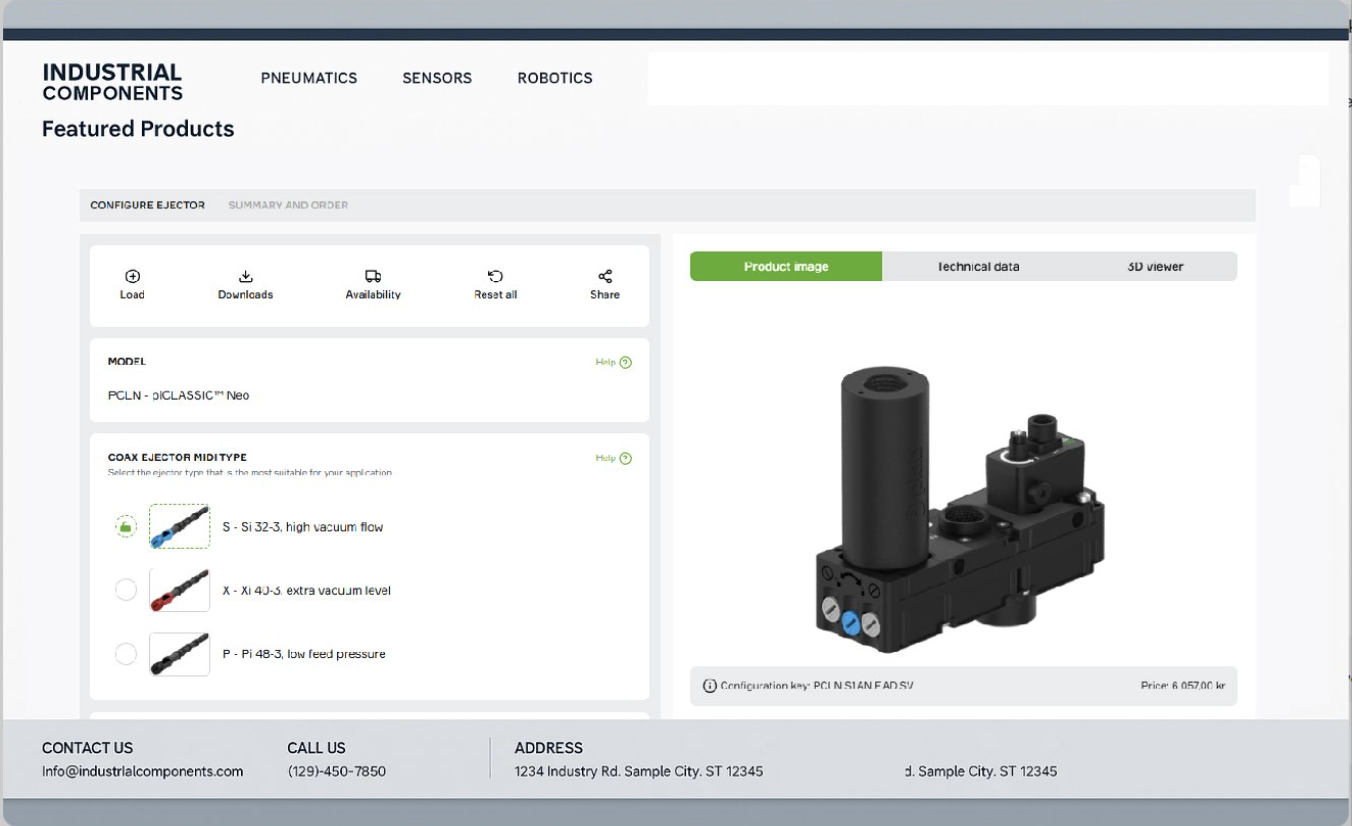

Self-service with embedded intelligence: Customers and partners can configure products, view 3D visualizations, and generate documentation, all in real time and without sales involvement.

-

ERP-integrated configuration logic: Every configuration connects directly to the ERP for automatic price retrieval, availability checks, and instant creation of non-existing item records to reduce error and duplication.

-

Modularity at scale: With 50+ configurators and 58,000+ configured products in ERP, Piab now designs products as modular and configurable by default to enhance speed, flexibility, and customer-driven design.

- Document automation: DocGen automates documentation, while integrated 3D visualization (added in 2024) allows users to explore and validate configurations visually before ordering.

The Impact

Accelerated sales and design confidence

Piab’s investment in Tacton CPQ has transformed its modular engineering and customer engagement approach, delivering measurable impact across efficiency, scalability, and experience:

-

40,000+ self-service sessions per month: Customers and partners actively use CSS to configure and order standard components directly.

-

6,000+ automatically generated documents per month: Proposal and technical documentation now require less manual input.

-

58,000+ configured items in ERP: A single digital thread connects design, pricing, and production data.

-

Greater design confidence and speed: Engineers and customers can visualize configurations instantly, reducing back-and-forth validation.

Looking Ahead

A platform for continued innovation

Piab is now looking to make its configuration capabilities embeddable to its partners, who make up a substantial portion of sales. They also plan to enhance their tool with configuration comparisons and accessory or spare part add-ons to the shopping cart.

Key Takeaways

Lessons in manufacturing

Build around modularity, not just speed

Piab’s success comes from using Tacton CPQ not only to accelerate quoting, but to scale its modular product architecture across the organization.

Support users through data integration

Real-time ERP synchronization ensures customers see accurate pricing and availability, turning configuration into a true e-commerce experience.

Make self-service an engineering asset

By enabling customers to “engineer” their own suction cups and systems online, Piab reduces internal workload while reinforcing product leadership.