How CPQ and CRM Integration Simplifies Selling for Manufacturers

Learn how CPQ and CRM integration personalizes selling, accelerates quoting, and enhances customer engagement for complex manufacturers.

Smarter, faster, and more personalized—manufacturers of complex products are feeling the pressure to deliver a more B2C-like buying experience. Traditionally, customer relationship management (CRM) has been the backbone of sales engagement, helping teams track relationships and manage workflows. According to Deloitte, 96% of industrial manufacturers either use or plan to use a CRM to enhance digital customer experiences. But CRM alone cannot support the complex configurations and real-time quoting that make smarter, faster, and more personalized possible.

True transformation happens when front-end sales engagement connects with dynamic selling capabilities like CPQ (Configure, Price, Quote). With CRM and CPQ integration, manufacturers can generate faster, more accurate proposals within the sales process, ensuring a seamless, high-confidence buyer experience.

Complex Product Sales: Where CRM Meets Its Limits

While CRM systems excel at tracking customer relationships and sales opportunities, they hit critical limitations when it comes to selling configurable products. A basic CRM can capture customer requirements and track opportunities, but it can’t guide sales teams through finding the optimal product configuration, nor can it validate complex technical rules or generate accurate pricing based on thousands of possible combinations.

For manufacturers of complex products, this creates a dangerous gap between understanding customer needs and translating them into viable solutions. Sales teams need more than just customer data – they need intelligent guidance to configure the right product for each unique situation.

What is the Role of CPQ in Sales?

CPQ (Configure, Price, Quote) software extends the CRM’s role by enabling sales teams to configure products, apply pricing rules, and generate quotes that reflect real-time business constraints. The software translates complex engineering rules and dependencies into simple questions about customer requirements, automatically suggesting compatible options and pricing and ruling out combinations that can’t be manufactured.

Though some CPQ platforms have light CRM functionalities, such as displaying accounts or opportunities, their core function is to turn customer intent into a viable, deliverable solution. CPQ integration eliminates the back-and-forth between sales, engineering, and finance, allowing sales to close deals faster.

How Does CRM and CPQ Integration Work?

Integrating CRM and quoting software allows account and opportunity data from your CRM to flow automatically to the CPQ. The sales professional can then tie a configured solution or product to a specific account opportunity. Once the sales rep generates a final quote, line item and pricing data syncs back into the CRM for better pipeline visibility and sales forecasting.

Imagine a medical device manufacturer using Microsoft Dynamics 365 to manage its sales pipeline and track customer opportunities. When a hospital requests a customized surgical instrument, the CRM captures key details (e.g., the hospital’s purchasing history, required specifications, pricing details, etc.). This data flows into the CPQ, which applies industry regulations, material constraints, and compatibility rules to ensure only valid configurations are created. Once the finalized quote is created, line item and pricing data syncs back to the CRM, ensuring sales teams have full visibility into the deal’s status and projected revenue.

The Cost of Siloed Systems

A fast, seamless sales process is your company’s greatest competitive advantage. Manual data entry and a slow, disjointed quoting process put revenue and trust at risk. When sales teams constantly rely on engineering for highly personalized product configurations and pricing, faster competitors step in. In addition, manual pricing adjustments leave further room for errors and volatility, resulting in customer mistrust.

Yet clunky integration between a CPQ and CRM can be just as costly as IT bottlenecks and poor scalability leads to slower sales cycles. Manufacturers can help their sales function hit the ground running by taking a thoughtful approach to integration.

The Benefits of Integrating CRM and CPQ: Trust and Confidence for Both Buyer and Seller

Accelerating deal closure is essential to winning today’s digital customers, but this requires sales teams to navigate complex configurations and pricing, often without deep technical expertise. A CPQ enhances the relationship building within the CRM by offering the support sales teams need to confidently sell highly personalized solutions.

1. Streamlined workflows keep sales moving

Automating the transition from opportunity to quote eliminates delays caused by manual processes and disconnected systems. Sales teams can access approved configurations and pricing instantly, reducing reliance on engineering, increasing quote volume, and speeding up quote generation from weeks to minutes.

2. Accurate quotes that build trust

Pricing errors and misconfigurations slow deals and weaken customer confidence. A connected CPQ and CRM ensure real-time accuracy, reducing back-and-forth revisions and accelerating approvals, so customers receive error-free proposals the first time.

3. Consistent buying experiences across every sales channel

Whether customers engage through a sales rep, distributor, or self-service platform, CPQ and CRM integration ensures pricing, configurations, and proposals remain consistent across channels. This creates a unified, seamless experience, no matter how or where the customer buys—and that consistency leads to greater trust.

4. Powerful visualization to support smarter buying decisions

Buyers want to see exactly what they’re getting, especially with complex products that must adhere to specific industry regulations or fit an intricate floor plan. Integrating CPQ with CRM enables real-time visualization earlier in the sales process, so you can ensure product-fit right away. Today’s CPQ platforms provide virtual and augmented reality visualization, as well as CAD integration, so customers can see how products fit into their working environment or meet regulatory compliance.

5. Stronger sales insights

Automatic data integration gives sales teams immediate visibility into deal progress, pricing trends, and customer buying behaviors. This leads to more accurate revenue forecasting and helps sales teams anticipate demand, optimize pricing, and close deals faster.

6. More cross-sell and upsell opportunities

With CPQ and CRM working together, sales teams can use past purchases, customer preferences, and configuration trends to offer the right complementary products at the right time. Automated recommendations and data-driven insights make cross-selling and upselling easier and more effective.

7. Confident sales teams

When experienced sales reps leave or product lines grow more complex, teams often struggle to keep momentum. CPQ integration equips sales teams with clear product options, automated pricing rules, and pre-approved configurations, so they can sell confidently without needing deep technical knowledge.

Best Practices and Considerations for CPQ Integration

No single piece of technology is a silver bullet. The best solutions align with your workflows to deliver real value and avoid overcomplicated processes. Consider these best practices for integration.

1. Weigh pre-built connectors vs custom integration

CPQ solutions with no- or low-code, pre-built connectors offer a faster, low-maintenance integration with CRMs, ERPs, and other sales tools. For small teams, this provides necessary speed-to-value. In contrast, custom integrations and open APIs require heavier development and troubleshooting from IT teams. However, this offers long-term flexibility for growing enterprises.

2. Prioritize capabilities built for complex manufacturing

Many CPQ solutions offer quoting, but not all can handle high product variance, complex configurations, and regulatory requirements. Integrating your CRM with a CPQ designed for manufacturing ensures accurate, compliant, and efficient proposals—without manual workarounds.

3. Ensure scalability and flexibility

System rigidity stops growth in its tracks. Look for a solution that adapts to growing product lines, integrates with multiple systems, and supports multi-site, multi-region, and multi-language capabilities.

4. Maintain data accuracy and consistency

Clean, structured data is critical for accurate pricing, forecasting, and reporting. Before integration, ensure CRM and CPQ data are aligned to prevent discrepancies in customer records, product configurations, and pricing rules.

5. Involve sales end-users early in the decision-making process

A successful integration requires end-user buy-in, specifically from sales. User adoption and continuous refinement are just as important as the technology itself. Ensure the CPQ enhances rather than complicates workflows. Consult your end-users in the evaluation and help them understand how these tools improve front-end sales engagement, rather than simply supporting back-end execution.

The Advantages of Using a Purpose-Built CPQ for Manufacturing

CRM-native CPQs offer convenience, but they often lack the depth needed for manufacturing, leading to manual workarounds, slower sales cycles, and errors. The best approach? Use the best CRM for managing customer relationships and the best CPQ for handling complex configurations and quoting. You’ll get greater alignment between sales, engineering, and production—without the compromise.

CRM-Native CPQ

- Easy CRM integration for basic quoting needs

- Simple setup for businesses with straightforward products

- Customization limitations for industry-specific needs

Purpose-Built CPQ

- Built for complex manufacturing workflows with advanced configuration rules

- Integrates with any CRM, ERP, or sales platform

- Scalable and adaptable to multi-channel sales and global operations

- Requires alignment with existing systems, but offers greater long-term benefits

Choosing the Right Type of Integration for Your Business

CPQ CRM integrations exist in several forms, but the approach you choose will depend on your tech stack, IT resources, and long-term business needs.

- Custom point-to-point integrations directly connect two systems, like CPQ and CRM, for fast data exchange. However, they need ongoing IT maintenance and don’t easily scale as business needs evolve.

- Middleware or integration platforms act as a central hub that bridges multiple systems, standardizing data flow and reducing the need for custom coding. They simplify complex integrations by ensuring seamless communication across CRM, CPQ, ERP, and other enterprise tools.

- Open APIs create a standardized way for systems to exchange data, enabling flexibility and control between CPQ, CRM, ERP, and other business integrations. While powerful, they require IT expertise to develop and maintain.

Transform the Buyer Experience with Tacton’s CPQ

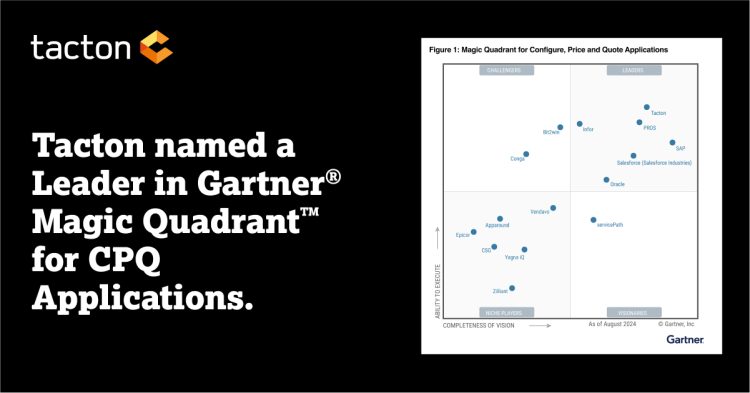

A purpose-built CPQ enhances your CRM capabilities and empowers manufacturers to sell complex products with B2C-like agility. Tacton transforms buyer engagement with industry-leading configuration, pricing, and quoting solutions, and is recognized as a leader in Gartner’s Magic Quadrant for CPQ applications.

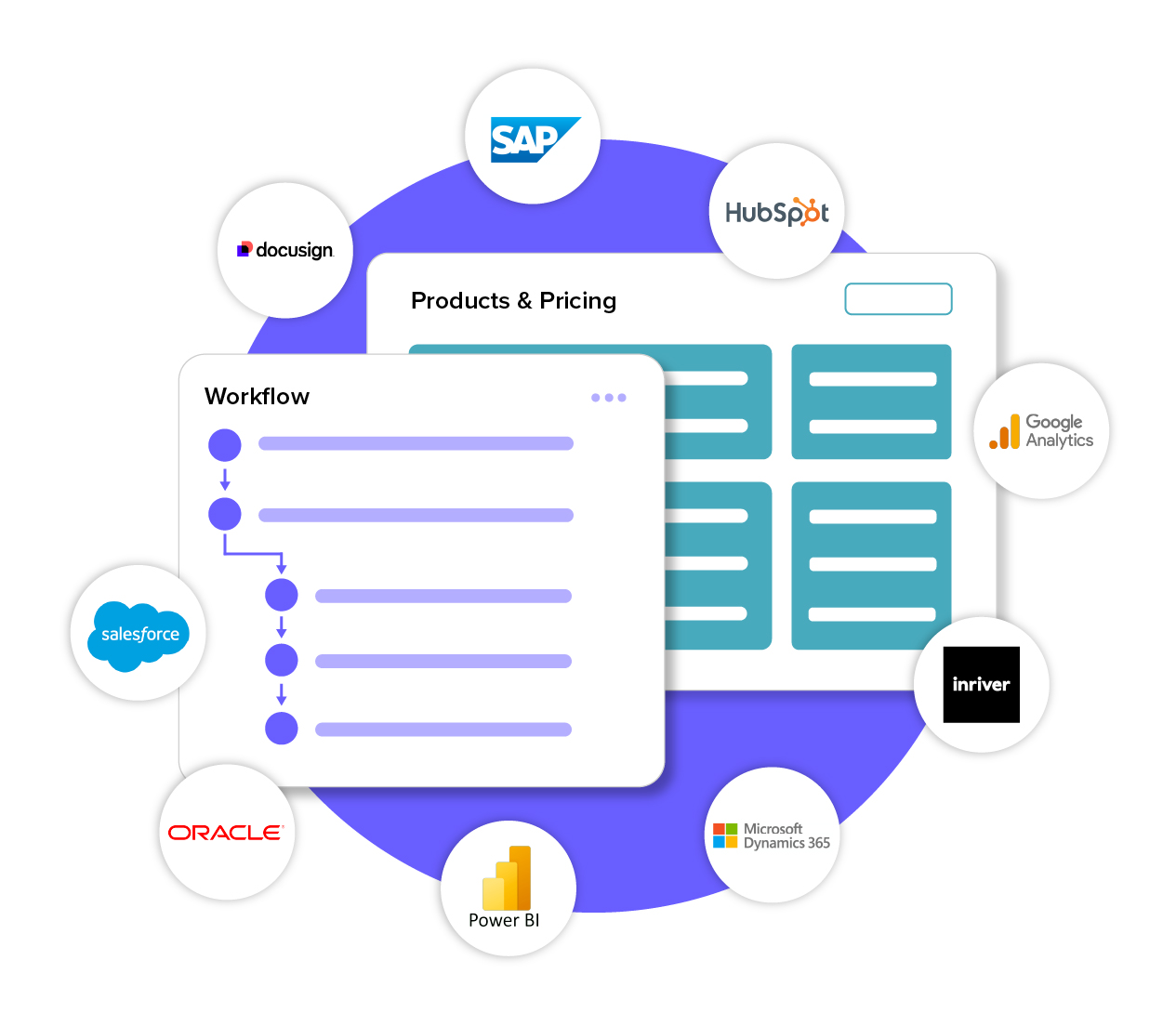

With Tacton, manufacturers can simplify CRM CPQ integration with platforms like Salesforce, Microsoft Dynamics 365, SAP Sales Cloud, and Oracle NetSuite, using pre-built connectors. Connect-to-Anything, powered by Workato gives manufacturers the ability to integrate with 600+ enterprise applications using a no-code solution. For enterprises needing deeper customization, system-agnostic integrations provide flexibility to connect with ERP, PLM, PIM, and other critical systems independently. With robust integrations, manufacturers can streamline operations across their entire value chain.