Tacton Celebrates 25 Years of Industry-Leading Innovation

Tacton is celebrating 25 years of CPQ industry leading innovation and looking forward to what's next for our industry leading configurator

Our Chief Executive Officer Bo Gyldenvang discusses the milestones and achievements we’ve seen at Tacton as we celebrate our 25th anniversary and takes a look into where we’re heading next!

This year marks a very special occasion — Tacton is celebrating 25 years as manufacturing’s Configure, Price, Quote (CPQ) leader.

In 1998, Tacton’s founders saw a massive unmet need for manufacturers of complex goods and heavy machinery: the need for customization, along with a growing number of interdependencies. Understanding this core challenge facing manufacturers, Tacton introduced manufacturing-specific CPQ technology to the market, bringing efficiency, sustainability and profitability to product variability.

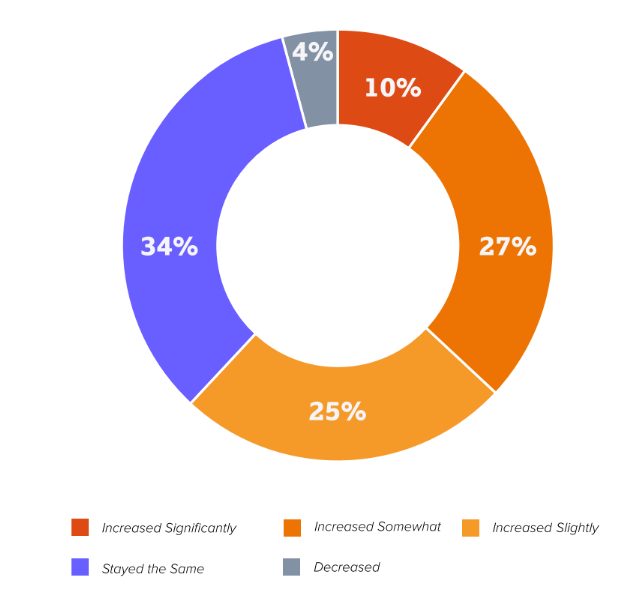

We were innovative and groundbreaking then and remain groundbreaking today. Since Tacton’s founding, we have grown from a Swedish configuration management startup to a global CPQ SaaS vendor, with customers including international manufacturing companies such as Siemens, Xylem and ABB. With 75,000 active users of Tacton licenses today, Tacton customers, on average, see a 34% increase in efficiency, a 30% increase in sales volume and boost their profit margins by 20%.

I’m proud to look back at just a few of the innovations Tacton has brought to the market, with a glimpse into what I see coming up next.

Serving our customers’ need for less complexity

Our clients and employees make us who we are today — as customer needs have evolved so too has our technology. One thing has remained constant, which is where we shine: Companies want less and less complexity. They want to get someone in to support their business requirements. They don’t want to think about all the nuts and bolts about their IT platform.

We make it as easy as possible for manufacturers with high product-complexity needs to run CPQ workflows and, as a result, improve their business outcomes, including profitability, revenue growth and greater efficiency. What’s more, this value gets passed down to our customers’ customers, enabling them to simplify and grow their businesses as well.

Our customers don’t want to use general CPQ software because they don’t want to compromise. They work with Tacton because we are born and bred in manufacturing. It’s why Gartner has named us a Leader in the 2022 Magic Quadrant for CPQ Application Suites.

As we reflect on this 25-year milestone and look forward to the future, we remain committed to pushing the boundaries of innovation to deliver what our clients need, even before they realize they need it.

Sustainability is going to be more and more important over the coming years. Just as important as the pricing and total cost of ownership (TCO) of a product, complex manufacturers need to adopt a sustainability perspective when configuring products to give their customers an improved understanding of the environmental impact of the products they’re procuring.

At Tacton, we prioritize transparency about the environmental impact of every single component that is used to make a product and offer the ability to change the makeup of end goods to be less taxing on the climate. As sustainability regulations and expectations from consumers and investors alike increase, we know how essential it is to meet every company’s needs and desires to reduce environmental impact and achieve their sustainability goals.

Another burgeoning area we’ve already helped manufacturers jump on is selling products as services. Just as the software industry has gone from an ownership-based model to a SaaS-based model, manufacturers are increasingly shifting to selling their products and services as subscriptions. It’s what customers want across industries — whether B2C or B2B.

And it’s great for companies too, helping generate predictable revenue and business success even in uncertain times. With Tacton’s subscription-based technology and service solutions, manufacturers can ensure smooth and resilient end-to-end operations while delivering a flawless digital customer experience when selling complex equipment and related services.

What’s ahead for Tacton

Tacton has been a leader for 25 years. And with consistent recognition from our customers, influencers in the manufacturing sector, and global research powerhouses like Gartner, we expect to stay a leader for the next 25.

While other technology vendors are starting to prepare their platforms for what’s next, we’re already ahead of the trends we see in the market today, including sustainability and the move to subscription models. We’re decades ahead of what any generalist vendor would be able to provide in the industry, bringing our manufacturing customers into the future.

We invite you to join us as we shape the future of smart manufacturing technologies for the next generation of manufacturers.