Innovation Redefined: Tacton’s Trail to CPQ Leadership for Manufacturers

Tacton has demonstrated CPQ leadership for manufacturers for over 25 years. Find out how we are setting the bar high for our customers!

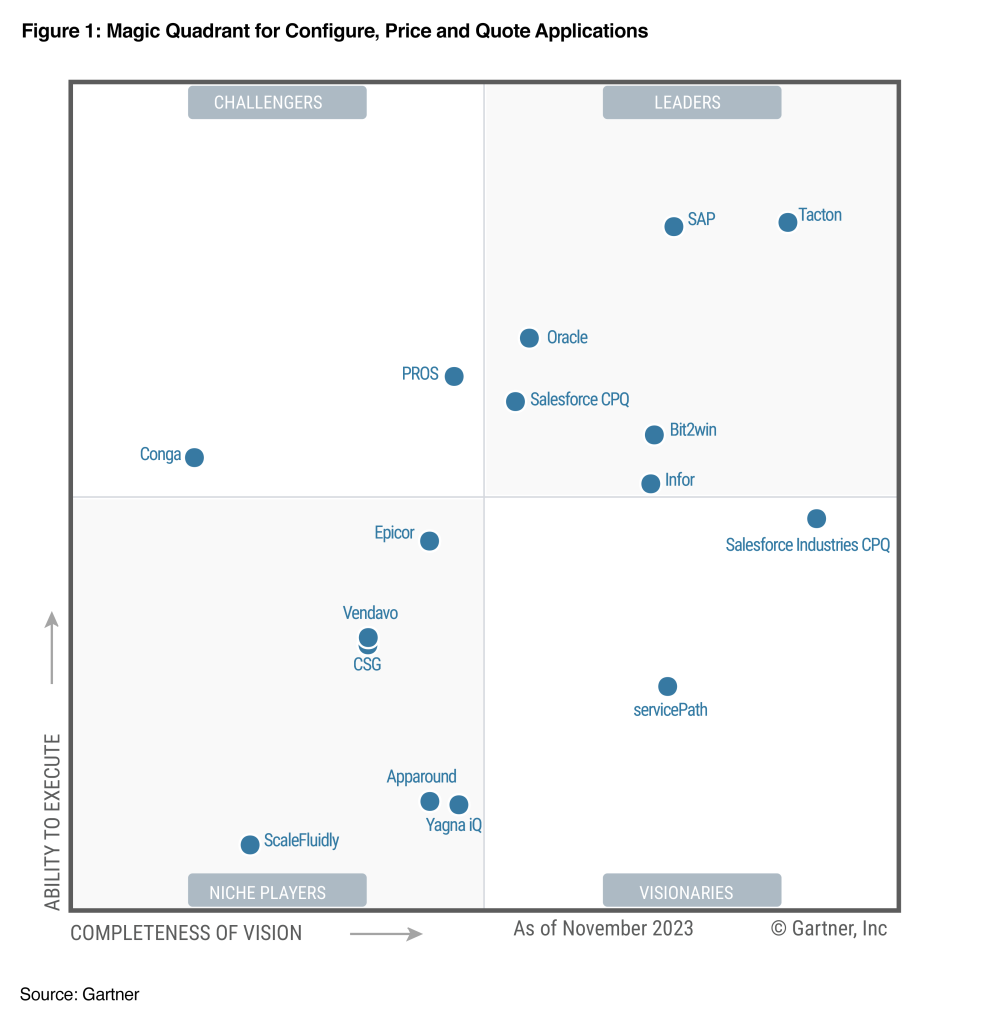

In case you missed it, Tacton was recognized in the Leaders Quadrant in the 2023 Gartner® Magic Quadrant™ for Configure, Price and Quote Applications. This is the second consecutive year we have been named a Leader, and the sixth year in a row we have made the quadrant.

With back-to-back acknowledgments as a leader, we have demonstrated our commitment to innovation and customer-centricity in delivering our cutting-edge CPQ solution. With 31% of manufacturers dealing with quality issues when quoting their products, many businesses are looking into how CPQ can revolutionize their quoting process. Let’s delve into the reasons behind Tacton’s consistent recognition and explore how we continue to redefine the CPQ landscape.

The #1 CPQ for manufacturing

Tacton CPQ is the top choice for manufacturers due to its unmatched configurability, seamless engineering integration, and guided selling capabilities. By providing real-time visibility into supply chain operations and personalized customer experiences, Tacton CPQ empowers manufacturers to optimize sales performance, drive operational efficiency, and foster stronger customer relationships. Tacton CPQ enables manufacturers to adapt to changing market dynamics and achieve long-term success in today’s competitive landscape.

Being #1 for manufacturing isn’t something we take lightly; we are helping manufacturers achieve improvements in quoting, sales and profit based on a Tacton customer value study:

Unparalleled product architecture

Tacton’s unparalleled product architecture stems from its modularized design, which offers both vertical and horizontal scaling capabilities. This architecture allows businesses to seamlessly adapt Tacton CPQ to their evolving needs without disruptions to ongoing sales operations. The flexibility of Tacton CPQ’s architecture ensures that changes can be made swiftly and seamlessly, ensuring that no sales deal is ever interrupted due to IT-related tasks.

Tacton CPQ architecture minimizes the burden on IT departments, as maintenance tasks are predominantly managed by the business users themselves. This empowerment of the business side not only reduces dependency on IT resources but also accelerates the implementation of changes, updates, and enhancements to the CPQ environment.

As a result of the product architecture, Tacton CPQ boasts exceptional performance, effortlessly handling large system configurations, intricate pricing models, and generating quotes with remarkable efficiency. Its robust design ensures swift processing and optimization, empowering businesses to streamline their sales processes while maintaining accuracy and reliability even in the face of complex configurations and pricing scenarios.

The product architecture of Tacton CPQ stands out as a solution where the agility and efficiency of the business are prioritized, ensuring uninterrupted sales processes and maximizing overall productivity.

Continuous, and timely product features

At Tacton we’ve unveiled several updates to our flagship product, Tacton CPQ, solidifying our position as the most comprehensive CPQ software tailored for manufacturers. Among the notable releases were Tacton CPQ Data Import Automation and Tacton Product Validations, which streamline processes and ensure accuracy in configuration.

Additionally, Tacton introduced an enhanced version of its Salesforce integration, enhancing seamless data flow and collaboration.

We’ve also made strides in Environmental Footprint Configuration and System Configuration, aligning with the growing focus on sustainability and operational efficiency. As sustainability becomes a larger focus for manufacturers, Environmental Footprint Configuration will help companies deal with conscious buyers and adhere to impending climate legislations.

Proven track record of customer success across industries

Our proven track record, expertise in complex configurable manufacturing, and strong industry fit in sectors like food processing, industrial machinery, and specialty vehicles bolster confidence in our customers. We’re able to work with leading companies because of our ability to address the unique challenges and complexities faced by manufacturers.

With our robust configurability and scalability, Tacton CPQ empowers manufacturers to efficiently manage intricate product configurations and streamline sales processes, resulting in faster quoting cycles and improved customer satisfaction. Moreover, our platform agnostic integrations to CAD, CRM, and ERP systems ensure seamless data flow and collaboration across departments, enhancing operational efficiency and accuracy.

Additionally, our focus on innovation, coupled with our commitment to customer-centricity, enables us to continually adapt to evolving industry trends and customer needs, solidifying our position as the preferred CPQ solution for manufacturers seeking to drive growth and competitiveness in today’s dynamic market landscape.

In closing

Customer demand is at an all-time high, and manufacturers are taking notice and adding new solutions to help them quote and create better customer experiences. We couldn’t be happier to be the trusted configuration partner of manufacturers such as TCP Wire, HMF Crane, Swift Lifts and more. Find out how CPQ can take your operation to the next level by reading our free eBook, “CPQ – A Mandatory Enterprise Solution for Sales Quoting” or schedule a quick chat with our experts!

Chat with our experts!