What is CAD Automation for Manufacturers?

Every manufacturer knows that the race to reinvent how they do business has been ongoing for years. In the past companies have received interest in their products from customers but have ran into a time-consuming issue. Creating detailed CAD drawings and a lengthy back and forth between sales and engineering. Finding solutions to automate these manual, and administrative tasks while speeding up your sales sounds pretty good, doesn’t it? It’s possible with CAD automation. But what is CAD automation for manufacturers?

A quick definition of CAD Automation:

CAD automation is the use of tools and technology to automate manual, administrative tasks. This adds value by promoting innovation for your engineers while helping your sales team provide accurate product drawings.

What are some common issues without CAD Automation?

Picture this: you’ve got a new prospect on the phone to discuss your product, the deal is going well, and the prospect chooses your business to manufacture their product. As your sales team gets more in-depth with the customer requirements, they begin the process of going back and forth with your engineering team to figure out what is technically possible. This is where issues tend to arise.

Creating custom sales quotes with drawings takes a lot of time. Without CAD Automation your sales team can promise something that may not be feasible. This causes a headache for your sales team and sends your engineering team scrambling to provide other options which may not be to the exact specification of the customer. All this is happening while your customer is contemplating what’s taking so long and considering other buying options.

How can CAD Automation help manufacturers?

Sell highly configurable manufacturing products with ease and confidence

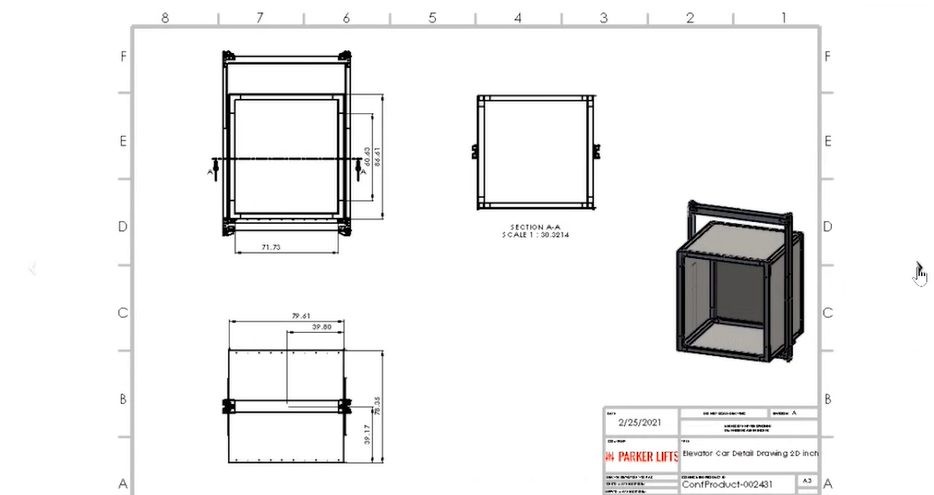

Let’s face it, product portfolios are large and with so many options can be confusing to not only your newest sales rep but even your more senior reps. With CAD automation your sales reps are equipped with approval drawings, and visual documentation that supports the final product your customer will buy. This enables quick and accurate product drawings to be done with accuracy and confidence. Giving your newest sales rep the same knowledge as your more experienced reps will enable them to onboard faster, intrigue customers, and ultimately sell products with ease.

CAD files clarify expectations between you, your customer, and your supply chain, so that you are all better prepared for the production, installation, and commissioning of the product. Generating and providing CAD files early in the sales process eliminates misunderstandings and costly errors, thereby ensuring reliability to the customer and promoting trust.

Accelerate sales with automation

Selling manufacturing products can be a long process and finding ways to accelerate the sale can be a key driver of winning deals. With CAD automation preapprovals your sales rep won’t have to worry about costly mistakes because the product logic is accurate. Without these mistakes, it’s possible to avoid delays, returns and discounts. This autonomy or your sales team also enables your engineering team to do more.

Check out where automation stands in manufacturers 2021 plans in our latest survey results

Enable your engineers to focus on innovation

Without your engineering team having to be involved in every sales case and administrative tasks they can focus on new product features and development. This can help your company find new ways to sell to new or existing customers.

Create an exciting and engaging customer experience

Customers don’t want to wait anymore for the slow back and forth just to produce CAD drawings. They want to see visualizations of their products in their real environments where they will be used. CAD and 3D visualizations work together to ensure a great customer experience. It’s even possible to get more technical with shop drawings, BOMs and analytics.

How does Tacton CPQ and CAD automation for manufacturers work together?

Configure, Price, Quote (CPQ) software and CAD automation work together by providing knowledge from your engineering team to your sales without having to go through constant meetings and emails. This happens by codeveloping product logic between your engineers and CPQ with a solver engine. Codifying product logic and validating it with info from CPQ. This enables your sales rep to sell what your engineers can create because it was co-developed with your engineering team. Eliminating guesswork. Needs-based guided selling meets engineering to dynamically generate 3D CAD models based on customer configuration requirements This empowers sales reps to generate CAD drawings without help from engineering.

|

Problem |

Solutions |

|

Mass customization requires sales engineering in every sales process. Sales cycles are long and cost per quote is spiraling |

Provide accurate CAD data for every product configuration proposed to end-customers as fast and easy as possible with CPQ and CAD Automation |

|

Manual handovers lead to a slow and inefficient quotation process that prolongs the sales cycle |

Simplify and automate handover processes between customers, sales, engineering, and factory |

|

Sales engineering needs to be involved in every sales case to provide detailed technical drawings to close a sale |

Automatically generate reliable technical CAD drawings in real-time without needing CAD skills or CAD software |

|

Misunderstandings and lack of technical product knowledge are leading to invalid quote requests |

CAD files align expectations between you, your customer, and your supply chain. The models can be updated with every choice that is made in the sales configurator, bridging the gap between customer requirements and engineering |

|

Lack of single source of product data |

CPQ with CAD automation ensures everyone operates on the same data from customer through the factory |

|

An inefficient and error-prone design process that requires too much administrative engineering work |

Automate manual processes and empower engineers to focus on innovation, new products, and value-creating tasks |

What are some other benefits of CAD and CPQ?

CAD + CPQ Implementation

- Fast and easy CAD mappings via point & click with no coding required

- Mappings can be validated immediately

- Directly connected to CPQ platform to exchange data in the background

Easy to use

- Simple and context-sensitive UI to speed up navigation

- Integrated help texts to speed up onboarding of new users

- UI matches UI of the host CAD system to ease up orientation

Easy to maintain

- Clear separation between configuration model and CAD mappings

- Easy recognition of already mapped elements

- Simply test individual values or a complete configuration

What are some tools Tacton CAD Automation works with?

Autodesk Inventor, Solidworks, and PTC Creo

Where to next?

CAD automation solves problems by standardizing and automating the design process that enables your sales team to move faster, and your engineers more time to focus on innovation. This is work that would directly affect the growth of the business and the bottom-line profit. CAD Automation will reduce costs for your business because it helps reduce common costly mistakes and errors. The automated process assures an even quality of the work performed, no matter how skilled, experienced, or attentive the engineer is, so it will reduce the claims costs as well.

Just like machines revolutionized the manufacturing industry by automating manual labor, CAD automation will revolutionize your design process by freeing up time for your design engineers and make them reach their full potential. Your business will be more cost-efficient, and more innovative.