CPQ and sustainability are two things that are shaping manufacturing in 2023 and beyond

Like any business, manufacturers are always evolving and adapting to new challenges to keep up with their competition, meet customer needs or new regulations. In the wake of the COVID-19 Pandemic manufacturers are beginning to look for new ways to lessen the odds of disruption to their businesses.

One major disruption that is on the horizon is climate change. The world is dealing with an uncertain future when it comes to climate change. Many countries are beginning to create laws and regulations that require manufacturers to adhere to certain sustainability standards. Companies investigate how they can make a positive contribution to the change in society.

These regulations will require manufacturers to find sustainable business models at a global level. In addition to meeting the standards, companies will also need to report these numbers to government agencies.

That’s why businesses are also still investing heavily in their Environmental, Social, and Governance (ESG) ambitions and requirements as a top priority in 2023 for manufacturers across industries.

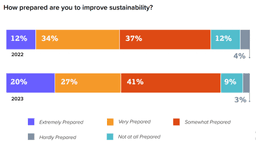

The rising demand for sustainable products from customers and regulations are driving manufacturers to find ways to sell sustainably. Check out how a recent Tacton survey highlighted the importance of improving sustainability for our respondents:

Preparing for upcoming regulations and laws is an important topic for manufacturers in 2023. 20% of the respondents we polled noted that they are extremely prepared to improve, that’s up 8% from 2022. Even the manufacturers who were hardly prepared decreased 3% from last year. This increase in preparation isn’t only because of regulations, but also because of customer demands.

That’s a lot of information to take in for manufacturers and finding a place to start their CPQ and sustainability journey can seem daunting but tackling these challenges head on can lead to new and exciting ways to sell while meeting regulatory requirements and customer demand.

Let’s take a closer look at what’s driving sustainability for manufacturers and where to start.

Who’s driving changes in sustainability?

Combating climate change will make everyone a stakeholder when it comes to finding a solution. Manufacturers, customers, investors and regulators will all have choices to make to find the best way to combat these challenges. Two of the main drivers of sustainability are regulations and customers.

Regulations and policies

The EU Green Deal and SEC´s proposed climate disclosure Rule in the United States are a few examples of initiatives countries are putting into place to better achieve goals of carbon neutrality. These can include items like carbon emissions impact, waste management and energy efficiency.

Many countries now require publicly traded companies to report on their sustainability practices and environmental impact. This helps to promote transparency and accountability and encourages companies to improve their sustainability performance.

Buyers: Customers are demanding more transparency from manufacturers. With buying power shifting to a younger generation, it’s important to deliver on their demands for more sustainable products. This provides an excellent opportunity for manufacturers who find ways to create sustainable products that can drive higher sales and profits.

Catering to customers who want sustainable products may seem challenging for manufacturers, but the demand is there, and it can lead to higher profits, and more visibility amongst buyers. Making customers happy is at the center of any good business, that’s one reason why leading manufacturers across the globe are starting to invest in sustainability to meet their customer needs.

Why does investing in sustainability make sense for manufacturers?

Manufacturing is typically slow to react to change, but manufacturers can’t afford to wait to invest in sustainable business practices. As we talked about, regulations and customer demand for sustainable products is here to stay. Here are five reasons manufacturers should invest in sustainability:

- Cost savings: Adopting sustainable manufacturing practices can lead to significant cost savings in the long run. For example, using renewable energy sources can reduce energy costs, while reducing waste and increasing efficiency can lead to lower operating costs.

- Improved brand image: Consumers are increasingly conscious of environmental and social issues, and they are more likely to support brands that are committed to sustainability. By investing in sustainable practices, manufacturers can enhance their brand image and reputation, which can lead to increased customer loyalty and sales.

- Compliance with regulations: Many governments around the world are introducing regulations that require manufacturers to reduce their environmental impact. By investing in sustainability, manufacturers can ensure that they comply with these regulations and avoid potential fines and penalties.

- Access to new markets: Many companies are now requiring their suppliers to meet certain sustainability standards. By investing in sustainable practices, manufacturers can access new markets and increase their business opportunities.

- Long-term viability: Sustainability is about creating a long-term, resilient business that can thrive in a changing world. By investing in sustainability, manufacturers can create a business model that is better positioned to adapt to changing market conditions and consumer preferences over time.

Creating new and exciting ways to buy sustainable products will be a key success factor in the upcoming years for manufacturers. By showing the environmental impact of any product purchase manufacturers will give their customers the best option to meet their needs while also adhering to their own possible regulations.

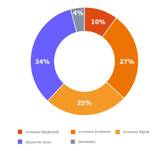

Reducing costs has become increasingly important to manufacturers, especially with looming uncertain economic conditions. In our latest survey we saw 59% of manufacturers investing in ways to reduce costs in 2023. Manufacturers who invest in sustainable selling can reduce oversizing of solutions, excessive waste and more.

Overall, a strong ESG plan that prioritizes sustainability, ethical practices, and social responsibility can help a company build a strong reputation in the marketplace. This, in turn, can lead to increased brand loyalty, customer trust, and reduced costs. Companies with a strong reputation are often able to command higher prices for their products or services, which can boost revenue and profitability.

How can manufacturers start their CPQ and sustainability journey?

Conduct a sustainability assessment: The first step is to assess the current state of sustainability within the organization. This includes evaluating the environmental impact of manufacturing processes, energy consumption, waste generation, and resource usage. This assessment will provide a baseline from which to measure progress.

Set sustainability goals: Based on the assessment, set sustainability goals that align with the company’s values and priorities. These goals should be specific, measurable, achievable, relevant, and timely.

Develop a sustainability strategy: Develop a sustainability strategy that outlines the actions needed to achieve the goals. This may include reducing energy consumption, sourcing sustainable materials, implementing recycling programs, and reducing waste.

Engage employees: Engage employees at all levels of the organization in the sustainability journey. This may include providing training, establishing a sustainability committee, and encouraging employee participation in sustainability initiatives.

Partner with suppliers: Work with suppliers to ensure they also prioritize sustainability. This may involve incorporating sustainability criteria into supplier selection, auditing supplier sustainability practices, and collaborating with suppliers to improve sustainability performance.

Track and report progress: Monitor and track progress towards sustainability goals and report on progress to stakeholders. This includes tracking key performance indicators (KPIs), such as energy consumption, waste generation, and emissions reduction, and reporting progress through sustainability reports and disclosures.

By following these steps, manufacturers can begin their sustainability journey and make progress towards more sustainable and responsible manufacturing practices.

What other solutions can manufacturers deploy to help with sustainability?

CPQ (Configure, Price, Quote) software can help with sustainability by streamlining the sales process and enabling companies to make more informed decisions about their products and services. Here are some ways CPQ can contribute to sustainability:

Optimize product configurations: CPQ software allows companies to create and configure products that are more efficient and sustainable. By using CPQ to optimize product designs, companies can reduce material waste, minimize energy consumption, and decrease the overall environmental impact of their products.

Enhance supply chain management: CPQ software helps companies better manage their supply chain, by automating processes such as vendor selection, procurement, and order fulfillment. By reducing supply chain inefficiencies, companies can minimize their carbon footprint and contribute to a more sustainable economy.

Enable data-driven decision making: CPQ software provides real-time insights into sales performance and customer behavior. This data can be used to inform strategic decisions, such as which products to prioritize or which markets to focus on. By making data-driven decisions, companies can optimize their resources and minimize waste.

In closing CPQ and sustainability are two factors that can influence manufacturers to make the right choices going forward:

Sustainability takes time and commitment from manufacturers. Seeing results may take time, but patience will be rewarded. Planning this shift towards more sustainable selling will create new opportunities and new markets to sell in. This all starts with a rock-solid plan and the commitment of the entire organization to deal with the changing landscape.

Find out how Tacton is helping manufacturers like Xylem and Plus Pack achieve these goals with our industry leading and trusted CPQ.