The state of manufacturing is constantly shifting to meet the needs of the industry, customer requirements and the laws and regulations in the places they operate. One monumental shift companies have started to grapple with is sustainability challenges and requirements.

Manufacturers are beginning to realize both the benefits of becoming more sustainable, and the pitfalls if they don’t question the status quo. Let’s look at the current state of sustainability in manufacturing, and what tools companies are using to deal with these challenges.

The basics: What is sustainable manufacturing?

According to the Environmental Protection Agency (EPA) “Sustainable manufacturing is the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. Sustainable manufacturing also enhances employee, community, and product safety.”

What is driving sustainable manufacturing?

Environmental Regulations

The world is dealing with an uncertain future when it comes to climate change. Many countries are beginning to create laws and regulations that require manufacturers to adhere to certain sustainability standards. These can include items like carbon emissions impact, waste management and energy efficiency.

These regulations will require manufacturers to find sustainable business models at a global level. In addition to meeting the standards, companies will also need to report these numbers to government agencies, investors, and customers to show they are meeting the goals.

Customer demands

With customers online more than ever, they are quickly able to do research on how companies produce products, treat employees, and disclose sustainability data. These conscious customers want to work with companies who champion sustainability and are transparent about how they do business.

With buying power shifting to a younger generation, it’s important to deliver on their demands for more sustainable products. And it pays to be sustainable, according to Capterra, 75-80% of consumers say that they’re willing to pay higher prices, ranging from a little more to significantly more, for sustainable products in comparison to unsustainable products. This provides an excellent opportunity for manufacturers who find ways to create sustainable products that can drive higher sales and profits.

An uncertain future

On the heels of a rough two years due to the COVID Pandemic, manufacturers are searching for ways to create disruption-proof operations. Climate change will create challenges like never before for manufacturers, resource scarcity and employee scarcity will be two major challenges.

Are manufacturers investing in sustainability initiatives?

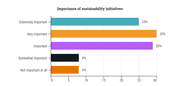

Recently at Tacton we surveyed 100+ manufacturers on their strategic goals and initiatives for 2022. One question we asked was about the importance of sustainability initiatives. 84% of respondents noted that sustainability was important to their 2022 goals.

It’s clear that sustainability is here to stay for manufacturers. Manufacturing will get requirements to support the environment by policy recommendations and tighter regulations and customer demands. These new requirements add even more complexity to an already challenging manufacturing sales process.

Manufacturers are facing an uncertain future if they don’t adhere to these sustainability standards, one product Configure, Price, Quote (CPQ) is helping manufacturers adjust to any regulation and customer demand. Let’s look at how CPQ is helping manufacturers with their sustainability goals. Let’s look at how CPQ is helping manufacturers with their waste reduction and sustainability goals.

How does CPQ help manufacturers become more sustainable?

CPQ in general is a way to put together a trusted, and valid configuration with approved pricing using a combination of rules and workflow.

Tacton CPQ is a unique solution in the CPQ space as it allows users to optimize the configuration of ecofriendly products without compromising the needs of the customer by giving them a full picture of the impact any product will have once it rolls off the production line.

CPQ also enables manufacturers to offer an optimized product that is in line with local regulations on emissions and other sustainability demands in their specific region. With CPQ it is even possible to allow faster product introductions that are aligned with a changing market.

What business value have manufacturers seen from their sustainability efforts?

When we apply Tacton’s unique features to manufacturers’ sustainability efforts, manufacturers can track certain parameters such as resource consumption and materials to ensure the most sustainable options are provided during the configuration process around the criteria that really matter for their end customers.

By showing such responsibility, manufacturers have also observed some “soft” benefits such as more demand as customers are increasingly looking to work with responsible organizations. Constraints and data management also provides a much faster time to market for manufacturers using CPQ which allows them to better adapt to regulatory changes and innovation which again will translate into a larger volume of sales and a reduction in sales lead time.

The time to act is now

Sustainability initiatives are here to stay. Countries across the globe are adding compliance and regulation rules faster than ever. These goals will need to be met to continue operations; manufacturers who fail to comply face an uncertain future. That’s why companies are looking towards CPQ to help deal with sustainability, and the added complexity it adds to everyday configurations. Find out how we’re providing trusted configuration for our customers by scheduling your demo today!