In manufacturing today, 43% of businesses rely on Excel for complex quoting, and 51% require engineering involvement for most quotes. One small error can trigger rework and lost revenue. It’s slow, risky, and inefficient, but it’s familiar. And that familiarity often overrides the urgency to update the tech stack with configure, price, quote (CPQ) software. However, the benefits of CPQ software extend beyond efficiency, enabling scalable, accurate, and customer-centric selling while protecting margins.

Manufacturers using CPQ, especially those using modern third-party platforms, are seeing measurable gains in quoting accuracy, speed, and buyer satisfaction. These benefits are outweighing the change fatigue associated with implementing CPQ and user adoption.

What is CPQ?

At its core, CPQ software automates and simplifies the process of configuring complex products, calculating accurate pricing, and generating fast, professional quotes. It replaces slow, manual quoting processes with a centralized, rules-driven or constraint-driven configuration engine that ensures every quote is accurate, optimized, and aligned to business goals.

Within the manufacturing industry, your customers may need to wait for days while your sales team liaises with various departments to determine what’s viable and create a quote that reflects the work involved.

Today’s customers don’t want to wait. And now they don’t have to, because one of the significant CPQ benefits is that salespeople can create and share sales quotes at the click of a button.

While this is the most basic function of CPQ software, contemporary offerings go much further to improve the customer experience. Let’s examine the pros of CPQ software and how CPQ benefits your organization.

Why Use CPQ: Real-World CPQ Benefits and Examples

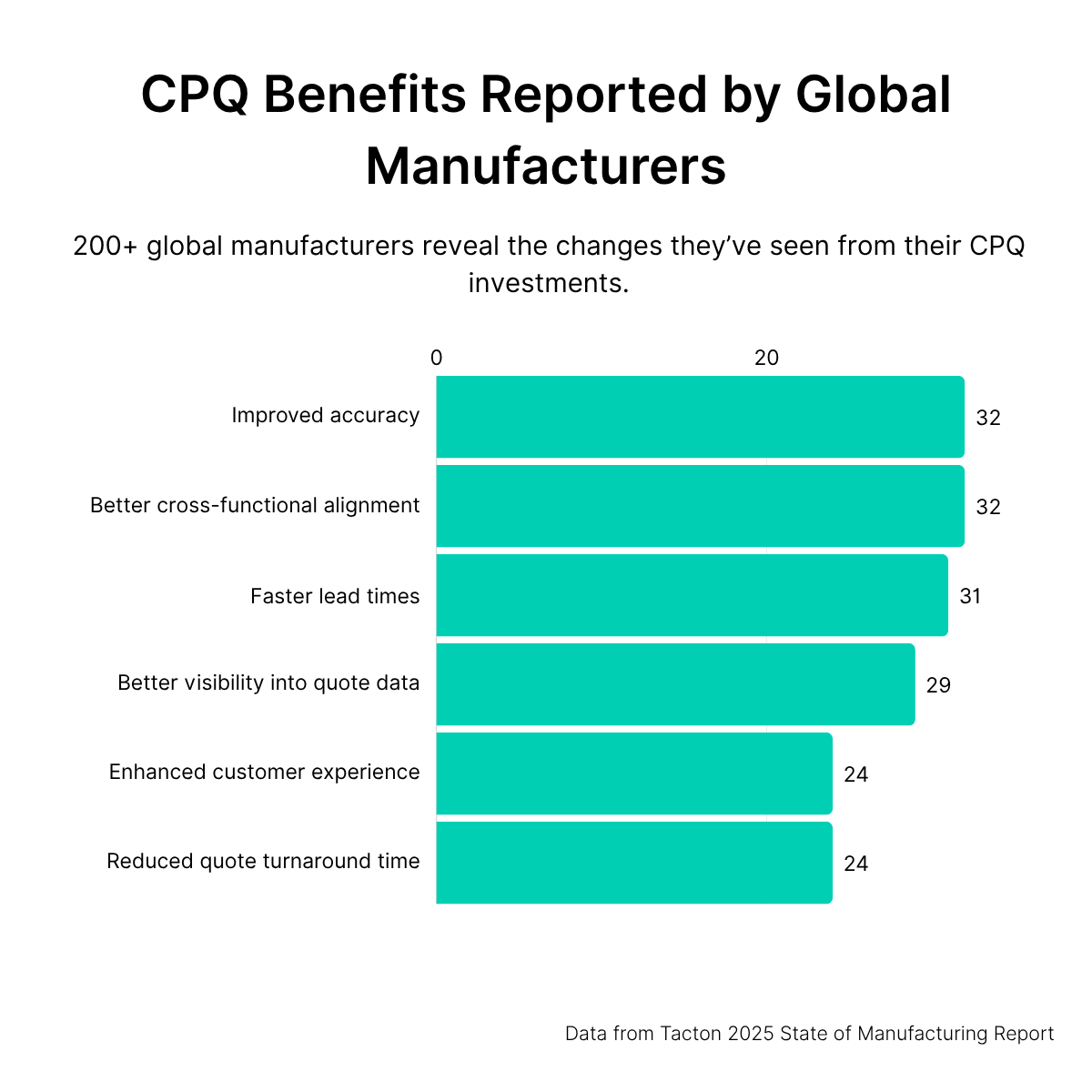

CPQ software for manufacturers delivers measurable results across the entire sales and production cycle. Companies that have invested in CPQ are seeing improvements in outcomes that directly impact competitiveness and profitability. According to our 2025 State of Manufacturing report, that looks like:

- 32% improved accuracy

- 32% better alignment between sales, engineering, and production

- 31% faster lead times

- 29% greater visibility into quoting data

- 24% enhanced customer experience

- 24% reduced quote turnaround time

How do these CPQ benefits translate into tangible business impact for manufacturers?

1. Protect Profit Margins

CPQ software addresses margin drains by embedding accurate configuration rules, pricing logic, and discount guardrails directly into the quoting process. Sales teams are guided to only sell what’s feasible and profitable, while pricing and approval workflows ensure quotes reflect up-to-date costs and margin targets. In addition, CPQ provides valuable information into sales data that informs teams of what sells and what isn’t worth the production effort.

Vantage Elevator Solutions and Bromma improved margin control and profitability by centralizing and optimizing their quoting processes with CPQ.

Vantage eliminated costly misquotes and rework by using constraint-based configuration to ensure every quote was accurate and manufacturable, protecting margins on every deal.

Bromma consolidated quoting through CPQ and integrated real-time analytics to track margin impact, forecast component demand, and fine-tune pricing. As a result, both companies gained greater control over pricing discipline, reduced cost-to-serve, and increased overall profitability.

2. Increase Quoting Turnover and Accelerate Revenue Generation

In fast-moving markets, quoting delays can mean lost deals. Quoting automation software streamlines the entire process, so sales teams generate accurate quotes without waiting on engineering or manual validation.

Siemens Energy’s turbine solutions are tailored to unique customer specifications, with hundreds of potential configurations. Previously, generating a customer proposal required up to eight weeks of effort and heavy involvement from engineering, with proposals stretching to 500 pages. Through their CPQ’s guided selling and a restructured product architecture, sales teams can now configure turbines and generate accurate quotes in minutes. This has unlocked greater throughput, faster response times, and reduced dependence on technical staff.

3. Improve Quoting Accuracy

Inaccuracies lead to a poor customer experience and, worse, lost deals. Manual processes are prone to errors in product configuration, pricing, and order details.

Your process must be perfect every time, because as many as 86% of customers will abandon a brand after just two bad experiences.

CPQ removes this risk by automating complex logic and enforcing consistent business rules.

When automating quoting, manufacturers consistently report fewer order errors, fewer production delays, and faster time to delivery. For example, before implementing CPQ, Durst, a global leader in digital printing solutions, relied on an Excel-based quoting process that often resulted in errors or inconsistent solutions, requiring lengthy approvals and renegotiations with customers. With CPQ software, Durst’s sales teams can generate thousands of error-free quotes per month, with pricing calculations that once took hours now completed in seconds.

4. Create a Consistent, Scalable Sales Process

CPQ enables manufacturers to scale without sacrificing accuracy or consistency, whether they’re expanding product offerings or selling through global dealer networks.

Configure-to-Order (CTO) manufacturing at scale

CTO allows manufacturers to deliver tailored products by assembling from modular, pre-engineered components. CPQ supports this by:

- Validating only buildable product combinations

- Automating BOMs and pricing for each configuration

- Reducing engineering involvement in every quote

This makes it possible to offer customized solutions without slowing down quoting or increasing risk, so manufacturers can scale product variety and sell without constant validation from technical experts.

Consistent quoting across dealers and resellers

CPQ standardizes how products are configured and quoted across all sales channels.

- Every dealer or partner uses the same logic, pricing, and product data.

- Quotes reflect the latest product rules and market-specific requirements.

- Customers get the same professional, reliable experience, no matter who they buy from.

For so many manufacturers who heavily rely on resellers, partner enablement is essential. Vencomatic Group, for example, faced growing complexity as it expanded its poultry farming equipment into new markets, each with its own set of regulatory requirements. Their CPQ acts as a dealer-ready configurator that automatically applies country-specific rules. Dealers now quote 40–50% faster, with consistent accuracy across markets and sales teams.

5. Improve Customer Satisfaction and Buyer Engagement

Customer satisfaction is the most critical battleground in modern-day business. That is why contemporary CPQ suites contain various tools to enhance customer satisfaction. So, it should be no surprise that companies using CPQ software see a 17% higher lead conversion rate.

CPQ software improves customer satisfaction rates through several techniques, including:

- Accurate quoting

- Self-service purchasing process

- Faster contracting process

- 3D visualizations of their orders

- Personalized service

Remember, 89% of consumers have said they will switch to a different brand if you don’t provide the service your prospects expect, making a CPQ an excellent part of your customer retention strategy.

Spectrum Industries, which designs and manufactures technology-integrated furniture solutions for education and commercial environments, digitized nearly 1,000 products and automated pricing, BOM generation, and 3D visualization using CPQ. As a result, they now deliver personalized, visually rich quotes 50% faster, creating a more engaging buyer experience that strengthens loyalty.

6. Align Teams Through a Single Source of Truth

Unlike spreadsheets, modern CPQ platforms are designed for seamless integration with core enterprise systems, including ERP, CRM, and CAD. This connectivity ensures that quoting processes remain aligned with production, pricing, inventory, and customer data, creating a more connected and efficient workflow across the organization. CPQ software also creates automated Bills of Material (BOMs), including sales BOMs, production BOMs, and engineering BOMs, with vital data sent directly to the ERP and supply chain management systems for streamlined productivity.

Tetra Pak’s success is a prime example. By tightly integrating CPQ with its ERP, CRM, and PIM platforms, Tetra Pak established CPQ as a single source of truth, providing reliable data across the entire sales process. With this foundation, Tetra Pak runs a coherent, globally consistent sales operation and sees greater alignment between different functions to seamlessly sell and deliver its products.

7. Data-Driven Decision-Making

With embedded analytics and real-time visibility into quoting data, CPQ provides valuable insights that simply aren’t possible with manual tools. Leaders gain the ability to track:

- Quote win/loss rates by region, product, or salesperson

- Margin performance across product lines or deal types

- Discounting patterns that erode profitability

- Configuration trends that highlight what’s selling—and what isn’t worth building

IMI, a global engineering leader with a highly complex product portfolio, uses CPQ to consolidate over 200 specialty tools into a single source of truth, affording the company greater visibility and control over its quoting and sales data. This visibility into their data has helped unify global sales processes, improve portfolio selling, and expand their customer reach.

By standardizing configurations and analyzing quote data in real time, IMI has reduced unnecessary engineering hours, shortened lead times, and enabled smarter supply chain planning

8. Support for Talent Shortages and Knowledge Transfer

According to global manufacturers, 34% of sales and engineering staff are expected to retire in the next five years. Sales rep turnover is significant, with some agents leaving organizations within two years of joining. Some industry estimates state that it can take 3.2 months to fully train a new addition to the team, followed by a long period for them to get up to speed.

That drains your resources, which is why CPQ is such a powerful addition to any business. CPQ reduces training time for new sales reps by embedding guided selling, configuration logic, and pricing validation directly into the quoting process. Even reps without deep technical knowledge can begin quoting complex products quickly and accurately. This technical knowledge exists in your systems even as long-time veterans retire and take tribal knowledge with them.

This was a key benefit for Conf Industries. Previously, much of the company’s product knowledge lived in the heads of senior technical staff. Now, with the entire product portfolio and configuration logic expressed in CPQ, the business is far less vulnerable to knowledge loss.

Why the Type of CPQ You Implement Impacts the Outcomes You Achieve

Not all CPQ systems are created equal, and there are unique benefits of CPQ software that homegrown CPQ tools may not offer in the long-term. Homegrown or heavily customized CPQ tools may seem sufficient and tailored at first, but they often fall short as business needs evolve.

In contrast, third-party CPQ software, especially purpose-built for complex manufacturing, offers scalability, speed, and strategic advantage that internal tools rarely match.

Manufacturers using third-party CPQ are seeing the following benefits:

- Better ability to configure complex products at scale (28% vs. 19% for homegrown)

- Stronger customer experience due to faster, more accurate quotes (28% vs. 13%)

- Fewer ongoing admin and maintenance challenges (2% vs. 26%)

- Faster lead times and shorter quote cycles, with improved alignment across teams

Implement CPQ with Tacton

The benefits of CPQ extend to every aspect of your sales process. You can improve your sales team’s operations, reduce errors throughout the process, and bolster the customer experience by letting your prospects operate independently. Our CPQ buyer engagement platform includes:

- Constraint-based configuration and dynamci pricing automation that guarantees valid, buildable product combinations

- Visual configuration and CAD automation that simplify even the most complex sales processes

- Document automation to streamline quote and proposal generation

- Deep integrations with ERP, CRM, and CAD systems to ensure seamless end-to-end workflows

- Easy administration makes your front and back office even more effective with data management tools, sales, workflows, and approvals.

- Data analytics feed your business intelligence to improve your offerings and how you serve your customers.

Ready to see what Tacton CPQ can do for you?